Artificial muscle as shock absorber

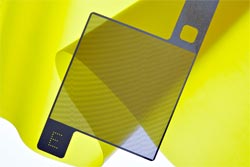

This image shows the lattice-shaped electrode in the foreground, and the elastomer in the background. © Ursula Raapke<br>

It is not very fun to ride a bicycle on a street plastered with cobblestones. At least the bike has a saddle seat filled with silicone. That lessens the shocks and bumps, and counteracts some of the annoying vibrations.

In a professional‘s eyes, the material in the saddle is an “elastomer” – a material that is yielding and malleable, like a rubber band. Engineers at the Fraunhofer Institute for Structural Durability and System Reliability LBF in Darmstadt are now working on the next generation: They are designing components made of elastomers that actively respond to unwanted vibrations, and dampen them more effectively than ever before.

Elastomers have been used in engineering for decades, such as shock absorbers in mechanical engineering or in the bearings for vehicle engines. Until now, they have had a purely passive effect on vibrations or impact collisions. It would be more effective if the elastomers were to respond proactively and counteract vibrations.

In the same way a tennis player slows down the ball on a drop shot by pulling back on her racket, an active elastomer draws out the energy from the vibration in a targeted manner by swinging in precise push-pull mode. Theoretically, this would make the vibration dissipate completely.

Elastomers vibrate under alternating current

There are already materials that are good for this purpose. “They are called ‘electroactive elastomers’,” explains LBF scientist William Kaal. “They are elastic substances that change their form when exposed to an electrical field.” The trick: apply an alternating current, and the material starts to vibrate. If there are smart electronics controlling the elastomers, making them vibrate precisely in push-pull mode, then unwanted vibrations in equipment or an engine will dissipate for the most part. To demonstrate that the principle works, the Darmstadt-based researchers created a model. Smaller than a pack of cigarettes, it is comprised of 40 thin elastomer electrode layers.

The experts call it a “stack actuator.” “The challenge was the design of the electrodes with which we apply the electric field to the elastomer layers,” as Kaal‘s colleague Jan Hansmann clarifies. Usually, electrodes are made out of metal. However, metals are relatively rigid, which impedes the deformation of the elastomer. Fraunhofer experts deliver an elegant solution to the problem: “We put microscopic-sized holes in the electrodes,” says Hansmann.

“If an electric voltage deforms the elastomer, then the elastomer can disperse into these holes.” The result is an actuator that can rise or fall a few tenths of a centimeter upon command – several times a second, in fact. To demonstrate these capabilities, William Kaal attaches a small mechanical oscillator to the device. When he turns it on, the oscillator begins shaking powerfully – the actuator has hit its resonance frequency perfectly. On the other hand, the instrument can actively absorb vibrations: If the oscillator is tapped by hand, it quickly settles down when the actuator vibrates in push-pull mode.

The LBF engineers believe one potential application for their stack actuator can be found in vehicle construction. “An engine‘s vibrations can be really disruptive,” says William Kaal. “The vibrations are channeled through the chassis into the car‘s interior, where the passengers start to feel them.” Of course, engines are installed meticulously, and yet: “Active elastomers may help further reduce vibrations in the car,” Kaal asserts.

When vibrations turn into power

The function of the stack actuator can also be reversed: rather than produce vibrations, the device can also absorb vibrations from its surroundings to produce energy. The principle works, and researchers have proven it. As they placed an electromagnetic oscillator on their stack actuator, it converted the vibrations into power. “That would be of interest, for example, if you wanted to monitor inaccessible sites where there are vibrations but no power connections,” Jan Hansmann believes – as he cites an example: the temperature and vibration sensors that monitor bridges for their condition.

The stack actuator technology has been largely perfected: “The manufacturing process can be readily automated. That is important for industrial mass production,” thinks Kaal. Nevertheless, endurance tests still have to show what the long-term viability of the intelligent actuators is like. Ultimately, they must be able to withstand harsh environments of the kind found in the engine compartment of a car.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…