Anti-aging elixir for solar cells

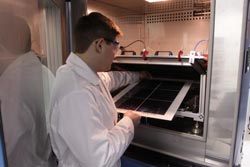

In this mechanical test stand the researcher examines the quality of silicone-encased solar modules. (© Fraunhofer CSE)<br>

Sometimes it‘s just a couple of cents that decide the success or failure of a technology. As long as solar power, for instance, is still more expensive than energy extracted from fossil fuels, photovoltaics will not be competitive on the broad open market.

“Power generation from solar energy continues to be reliant on public subsidies – this is no different in the USA than in Germany,” explains Christian Hoepfner, Scientific Director of the Fraunhofer Center for Sustainable Energy Systems CSE in Cambridge, Massachusetts, USA. “If we want renewable energy to penetrate the global market over the long term, then we must ensure it gets cheaper.”

There are no silver bullets to reach this target: Efficiency cannot be arbitrarily increased, and it is expensive to produce solar cells and modules. If you want to change something here, you have to solve a puzzle with many variables: Engineering teams around the world are searching for new technologies and production methods to make cells and modules cheaper, more efficient, more durable and reliable.

Silicone – steady and resilient

Silicone is one of the promising materials. It is a highly unusual substance – neither inorganic crystal nor organic polymer – but related to both. While PV modules have been encapsulated with silicones, until now, however, they were not widely used for laminating solar modules. Lamination is a protective coating that surrounds the fragile silicon wafer. Today most manufacturers of photovoltaic cells use ethylene-vinyl acetate, or EVA for short.

In order to determine if silicone could replace the ethylene-vinyl acetate a team of experts worked together: researchers from Fraunhofer and from Dow Corning Corporation, the world‘s largest manufacturer of silicones used in medical technology, cosmetics, the automotive industry, paper processing and electronics. The scientists coated photovoltaic cells with liquid silicone. “When the silicone hardens, it encases the cells; the electronic components thus have optimal protection,” says project Manager Rafal Mickiewicz. The experts at CSE constructed prototypes from the silicone-laminated cells, and tested these photovoltaic modules in a climate chamber at low temperatures and under cyclic loads. Afterwards the module performance was tested with a light flasher. In addition the researchers used electro-luminescence-imaging for the detection of micro cracks. A comparison of the results with those of conventional solar modules proved that silicone-encased photovoltaic modules are more resistant to cyclic loading of the type modules experience in strong winds, in particular at a frosty minus 40 degrees Celsius.

“Dow Corning Corporation collaborated with researchers at the Fraunhofer CSE Photovoltaic Modules Group for two years. This collaboration significantly improved our understanding of the materials requirements of our solar modules, particularly in regard to sustainability and output,” concludes Andy Goodwin, Global Science & Technology Manager, Dow Corning Solar Solutions.

In the meantime, the tests have been published at the 26th European Photovoltaics Solar Energy Conference in 2011. “The study results demonstrate that silicone lamination is well-suited for certain applications, because the silicone protects the fragile components on the inside well, and moreover, withstands severe temperature fluctuations. With this technology we can, for instance, make modules with thin Si cells more robust,” concludes Mickiewicz.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Bringing bio-inspired robots to life

Nebraska researcher Eric Markvicka gets NSF CAREER Award to pursue manufacture of novel materials for soft robotics and stretchable electronics. Engineers are increasingly eager to develop robots that mimic the…

Bella moths use poison to attract mates

Scientists are closer to finding out how. Pyrrolizidine alkaloids are as bitter and toxic as they are hard to pronounce. They’re produced by several different types of plants and are…

AI tool creates ‘synthetic’ images of cells

…for enhanced microscopy analysis. Observing individual cells through microscopes can reveal a range of important cell biological phenomena that frequently play a role in human diseases, but the process of…