A folding ceramic

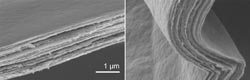

Layered ceramic paper: Scanning electron micrographs show the stacked layers of vanadium pentoxide and water in the composite. The material is so elastic and tough that it can be bent (right-hand image). © Advanced Materials/Stuttgart University <br>

Scientists in Stuttgart are currently doing things to a ceramic, which would normally result in a pile of shards. They were the first to produce a paper-like material from a vanadium pentoxide ceramic which is as hard as copper, yet flexible enough to be rolled up or folded. The material is also different from other ceramics, as it is electrically conductive.

In a project funded by the German Research Foundation (DFG), the scientists from Stuttgart University, the Max Planck Institute for Intelligent Systems and the Max Planck Institute for Solid State Research produced the ceramic paper consisting of conductive nanofibres of vanadium pentoxide in a straightforward and simple way. The ceramic paper’s special mechanical properties are derived from its structure, which resembles that of mother-of-pearl. The material looks promising for applications in batteries, flat and flexible gas sensors and actuators in artificial muscles.

What material scientists have only learned in the last few decades, Mother Nature has practised for millions of years: transforming materials with rather modest mechanical properties into new, extraordinarily hard, tough and elastic ones, by giving them a sophisticated nanostructure. In molluscs’ shells, for instance, hard but brittle aragonite platelets are stacked in layers like bricks and joined using a protein “mortar”, thus creating the hard, yet elastic and sturdy mother-of-pearl.

This natural composite served as the model for the research carried out by scientists working with Žaklina Burghard and Joachim Bill from the Institute of Material Science at Stuttgart University, which is set up at the Max Planck Institute for Intelligent Systems on the Stuttgart Max Planck campus. Together with their colleagues from the Max Planck Institute for Intelligent Systems and the Max Planck Institute for Solid State Research, they used the hard but brittle ceramic vanadium pentoxide to produce an elastic and electrically conductive paper.

The fibres assemble themselves into a transparent orange paper

First, the scientists synthesised nanofibres of vanadium pentoxide using water-soluble vanadium salt according to the procedure known for over 20 years. The rather unusual feature of this ceramic is that the fibres conduct electricity. This is possible because the metal oxide chains contain weakly bound electrons which can hop along them.

The conductive fibres assembled into an elastic and strong paper – once the Stuttgart-based scientists had created the necessary conditions. They distributed the nanofibres suspended in water very thinly on a substrate, and afterwards let the aqueous film dry for several hours at room temperature, and then a few more hours at 40°C, slowly reducing the humidity in the climate chamber. This slow process allowed the fibres to assemble themselves into precisely parallel patterns. Finally, they annealed the film at 100 and 150°C, thus producing a transparent, orange paper whose thickness could be modified by changing the amount of nanofibre solution used (between 0.5 and 2.5 micrometres).

The ceramic paper is more elastic and stronger than mother-of-pearl

“The paper can be folded like an accordion or rolled up,” Žaklina Burghard says. In fact, in this aspect, the ceramic paper is probably even superior to its natural model. “Although mother-of-pearl exists in small, helical sea shells in nature, this rigid biomineral cannot be folded like a normal sheet of paper.” The ceramic paper is not only more elastic than mother-of-pearl, it is also harder. What is more, it conducts electricity. “However, the conductivity along the paper fibres is much greater than across them,” Žaklina Burghard says.

The reason for the varying conductivity of the paper depending on the direction in which the scientists measure it, also explains its remarkable mechanical properties. They are both a result of the material’s structure, which is formed in a self-assembly process under the conditions created by the scientists in Stuttgart.

A cross-section shows a structure much like a brick wall

The structure begins with the assembly of the nanofibres, which was known prior to the Stuttgart project. The fibres consist of two vanadium pentoxide layers with a layer of water in between. Several fibres stack on top of one another laterally, forming slabs. The slabs also stack laterally, but staggered, on top of each other, so that the structure of the layered material will likely resemble a brick wall in a cross-section, where the vanadium pentoxide slabs make up the bricks embedded in a water layer that surrounds them like mortar.

It is this combination of hard ceramic and soft water in the special nanostructure that makes the paper hard, strong and pliable. It also results in high conductivity in the paper plane and low out-of-plane conductivity. However, the electricity is not only transported by the electrons that move along the nanofibres, but also by ions in the water layers between the ceramic.

Both the electrical properties and the mechanical properties of the paper therefore vary according to the water content. By drying and annealing the material, the scientists mainly remove weakly bound water to make the ceramic fibres form a denser structure. Since this also reinforces the bonds between the nanofibres, it makes the paper harder and more rigid.

Potential applications: batteries, gas sensors and artificial muscles

“Thanks to its excellent mechanical performance, combined with the electrical and chemical properties, the ceramic paper is suitable for numerous different applications,” Burghard says. For instance, ions could be incorporated between the vanadium pentoxide fibres and slabs, which would make the paper suitable as electrode material for batteries. “Since the paper is structured in regular and homogeneously shaped layers, ions can move efficiently in a particular in-plane direction,” Žaklina Burghard explains. Batteries with ceramic paper electrodes could therefore be charged quickly, but also discharged quickly to allow for high current densities. Industry is already showing a keen interest in using the paper in rechargeable batteries.

Furthermore, its capacity to accommodate ions makes the ceramic paper attractive to other fields. Since electrons can be made more mobile in vanadium oxide thanks to molecular interaction, it is also suitable for gas sensors. Owing to the small vanadium oxide nucleus, which has been reduced to just a few micrometres, instruments can be made smaller. In addition, the ceramic paper could give life to artificial muscles. When foreign ions accumulate in the composite, it expands. As an actuator controlled by the number of intercalated particles, the ceramic paper could push or pull objects down to microscopic size.

“In the ceramic paper, we combine the best of two worlds,” Žaklina Burghard says: “the versatile chemical properties of vanadium pentoxide and the mechanical properties of mother-of-pearl, a material that has been optimised over millions of years.” However, her team has no intention of stopping there: the scientists want to combine the ceramic paper with further materials to provide it with even more versatile and better properties.

Contact

Zaklina Burghard,

Max Planck Institute for Intelligent Systems, Stuttgart site, Stuttgart

Email: burghard@mf.mpg.de

Prof. Dr. Joachim Bill,

Universität Stuttgart

Phone: +49 711 685-61945

Email: bill@imw.uni-stuttgart.de

Original publication

Zaklina Burghard, Andreas Leineweber, Peter A. van Aken, Thomas Dufaux, Marko Burghard and Joachim Bill

Hydrogen-bond reinforced vanadia nanofiber paper of high stiffness

Advanced Materials, article first published online 7 March 2013; DOI: 10.1002/adma.(201300135)

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Bringing bio-inspired robots to life

Nebraska researcher Eric Markvicka gets NSF CAREER Award to pursue manufacture of novel materials for soft robotics and stretchable electronics. Engineers are increasingly eager to develop robots that mimic the…

Bella moths use poison to attract mates

Scientists are closer to finding out how. Pyrrolizidine alkaloids are as bitter and toxic as they are hard to pronounce. They’re produced by several different types of plants and are…

AI tool creates ‘synthetic’ images of cells

…for enhanced microscopy analysis. Observing individual cells through microscopes can reveal a range of important cell biological phenomena that frequently play a role in human diseases, but the process of…