Climate-friendly architecture thanks to natural folding mechanisms

Movable components in buildings such as blinds, the structure of which is based on cones of coniferous wood. Photo: C. Zollfrank/ TUM

Worldwide, the use of buildings accounts for 40 percent of total energy consumption. Around half of this is used for climate control. Although blinds and other mobile facade elements can be used to optimize the building shell's transparency to heat and light, their electric motors also require energy to move these systems.

“Sustainable architecture urgently requires new materials if it is to live up to the high energy efficiency and climate protection requirements”, says the chemist, forest scientist, and materials researcher Professor Cordt Zollfrank. At the Chair of Biogenic Polymers on the Straubing Campus for Biotechnology and Sustainability of the TUM, he is researching the related basic principles. His goal is to develop drive elements and actuators which are able to convert signals into mechanical movements without consuming energy.

Together with architects, civil engineers, and botanists, he has found futuristic methods that allow natural mechanisms to be used to improve the energy balance of buildings. In a joint article in the specialist journal “Advanced Materials, the team reports on the status of the research in this area, and demonstrates the possibilities of the models from the plant world.

Material replaces motor

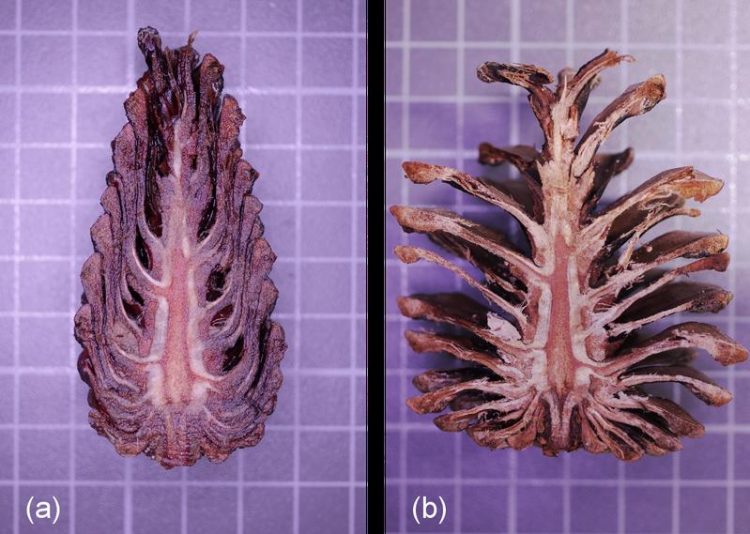

Ripe pine and fir cones close their scales when it rains in order to protect the seeds. However, when it is dry, they open up and release them. During this movement, the composition of the cell walls plays a crucial role. They are composed primarily of lignin, which does not swell much, and cellulose, which is good at swelling up. Due to the different orientation of the cellulose fibrils in the tissue of the scales, they curve inwards when humidity is high, and outwards when it is dry.

“The exciting thing about this is that the energy for these movements does not come from metabolic processes, but solely from physical mechanisms and material properties”, says Professor Zollfrank. Via the combination of materials with varying swelling propensities, he has already succeeded at developing such biomimetic drive elements, called actuators. These elements are also composed of two layers of materials which absorb varying amounts of liquid and behave similarly to their naturally occurring models.

Overcoming physical limits

However, before they can be used on a large scale in architecture, the material researchers still need to solve one problem which affects scalability: The larger the cell or the tissue, the longer the time required for the water to penetrate its pores towards the inside. Something that takes two hours in a pine cone would take several years in a building. Hence, in order to utilize the hydraulics of pine cones for applications in architecture, a physical limit will first need to be overcome.

All a question of the right links

For this purpose, Zollfrank proposes a type of restructuring process at the material level. “We decouple the tissue size and take the whole thing to the magnitude of an individual cell”, he explains. Via cleverly chosen cross-links, a loose cell complex is created whose individual components nevertheless still act like individual cells and absorb water extremely rapidly.

“The question now is how such cross-links can be designed as efficiently as possible and how to create them in any size”, says Zollfrank. However, for later practical applications, he can also imagine porous biopolymer materials whose pores are filled with an extremely hydrophilic liquid (hydrogel). Material researchers are already working on this. It is only a matter of time before we find out which solution will ultimately make its way into the architecture of the future.

Publication

Simon Poppinga, Cordt Zollfrank, Oswald Prucker, Jürgen Rühe, Achim Menges, Tiffany Cheng, and Thomas Speck: Toward a New Generation of Smart Biomimetic Actuators for Architecture, Advanced Materials 10/2017. DOI: 10.1002/adma.201703653.

Contact

Prof. Dr. Cordt Zollfrank

Chair of Biogenic Polymers

Technical University of Munich

Phone: +49 9421 187 450

Mail: cordt.zollfrank@tum.de

https://www.tum.de/en/about-tum/news/press-releases/detail/article/34331/ Article

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…