3D printer sensors could make breath tests for diabetes possible

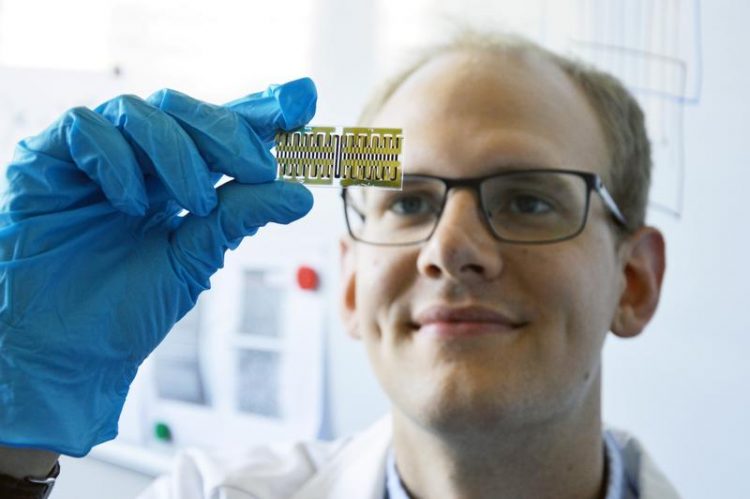

Highly sensitive gas sensors from the 3D printer on a glass slide Photo: Julia Siekmann, Kiel University

The production of highly sensitive sensors is a complex process: it requires many different steps and the almost dust-free environment of special cleanrooms.

A research team from Materials Science at Kiel University (CAU) and from Biomedical Engineering at the Technical University of Moldova has now developed a procedure to produce extremely sensitive and energy-efficient sensors using 3D printing.

The simple and cost-effective production method is also suitable for industrial production, the team recently explained in the renowned specialist journal Nano Energy. Their sensor, which they present here, is able to precisely measure the concentration of acetone vapor using a special structuring at nano level.

As the acetone concentration in the breath correlates with blood sugar levels, the research team hopes to have made a step towards producing a breath test for diabetics that could replace the daily checking of their blood sugar levels by finger pricks.

Larger surface makes sensor more sensitive

The special surface of the new sensors is visible under a high-resolution electron microscope: molecules of gases like acetone are particularly easily entangled in a thicket of nanowires around just 20 nanometres in diameter. The nano-wires-spikes increase the size of the sensor surface and so create its high level of sensitivity.

“To make this special structure we heat simple microparticles of metal until numerous fine nanowires and nanospikes form on them. With a specially developed ink we can apply these particles with precision to various surfaces using a 3D printer,” said Leonard Siebert, explaining what is known as “Direct Ink Writing”.

As a doctoral researcher in the “Functional Nanomaterials” working group at the CAU, he is researching additive production technologies as 3D printing, among other things.

Multi-faceted procedure for acetone and other gases

Due to their special sensor concept the automatised 3D printing process presented in the study can be performed in normal ambient air. In this way, several sensors are created at the same time within a few minutes, something which used to take a couple of hours in cleanrooms. The starting material can also be varied in a targeted manner, changing the size and structure and enabling the detection of a certain gas.

“This is still, first and foremost, basic research, but this principle could be used in the future to develop sensors for hydrogen or other explosive and hazard gases,” Professor Rainer Adelung, head of the working group at Kiel University, is convinced.

The metal particles as the starting material for the sensors have to be of a certain size in order to form the special wires and nanospikes. “The correct and high ratio between surface and volume is crucial,” explained Dr Oleg Lupan from Biomedical Engineering at the Technical University of Moldova.

As a Humboldt fellow, he researched this process for six months as part of the working group in Kiel. What is advantageous for the sensitivity of the sensors proves to be a challenge when it comes to their production: whilst smaller particles can be applied to surfaces easily using established techniques such as spraying or vacuum evaporation systems, the microparticles used here are already too large for this.

“For this reason, we considered to use 3D printers to apply the micro-particles,” said materials scientist Siebert. “The knowledge of materials and devices of colleagues from the Technical University of Moldova and our experience in nanomaterials and 3D printing complement each other perfectly here.”

Energy efficiency enables mobile applications

When organic molecules meet the numerous wires in the finished sensor, they react strongly to one another. By doing so, they change the resistance of the sensor and release clearly measurable signals. In principle, however, only a very small volume of electricity passes through the thin wires.

“So our sensors only use very little energy,” explained Lupan. “This makes small portable measuring devices conceivable, too, which can be read directly via smartphone, for example.”

The researchers hope this could enable future use of the sensors in mobile, portable breath tests for diabetics. Instead of checking their blood sugar levels by finger prick several times a day, diabetics could measure the acetone content of their breath.

The metabolic product is created when there is a lack of insulin and is emitted via the breath. The highly sensitive sensors could determine acetone values of under 1 ppm (particles per million air molecules), reported the study, while the breath of people with diabetes type I or II has an acetone content of more than 2 ppm.

This work was achieved with support from the research group 2093 “Memristive devices for neuronal systems” at Kiel University.

Photos are available for download at:

http://www.uni-kiel.de/de/pressemitteilungen/2020/091-3D-Druck-1.jpg

Caption: On the glass slide are highly sensitive gas sensors from the 3D printer.

© Julia Siekmann, Kiel University

http://www.uni-kiel.de/de/pressemitteilungen/2020/091-3D-Druck-2.png

Caption: The sensor surface under the microscope: the research team grows tiny wires and spikes from metallic microparticles that are particularly good at trapping gas molecules.

Copyright: Functional Nanomaterials working group

http://www.uni-kiel.de/de/pressemitteilungen/2020/091-3D-Druck-3.jpg

Caption: With the aid of a special ink, the crucial microparticles can be applied to surfaces using a 3D printer.

© Julia Siekmann, Kiel University

http://www.uni-kiel.de/de/pressemitteilungen/2020/091-3D-Druck-4.jpg

Caption: Ideal combination: doctoral researcher Leonard Siebert (left) researches 3D printing processes at the CAU, Dr Oleg Lupan develops special materials and sensors at the Technical University of Moldova.

© Julia Siekmann, Kiel University

Details, which are only a millionth of a millimetre in size: this is what the priority research area “Kiel Nano, Surface and Interface Science – KiNSIS” at Kiel University has been working on. In the nano-cosmos, different laws prevail than in the macroscopic world – those of quantum physics. Through intensive, interdisciplinary cooperation between physics, chemistry, engineering and life sciences, the priority research area aims to understand the systems in this dimension and to implement the findings in an application-oriented manner. Molecular machines, innovative sensors, bionic materials, quantum computers, advanced therapies and much more could be the result. More information at http://www.kinsis.uni-kiel.de

Prof. Dr. Rainer Adelung

Kiel University

Working Group “Functional Nanomaterials”

Phone: +49 431 880-6116

E-Mail: ra@tf.uni-kiel.de

Leonard Siebert

Phone: +49 431 880-6321

E-Mail: lesi@tf.uni-kiel.de

Oleg Lupan, Ph.D.

Technical University of Moldova

Department of Microelectronics and Biomedical Engineering

Phone: +373 22 509-910

e-mail: oleg.lupan@mib.utm.md

Web: https://utm.md/en/research-dmbe/

Facile fabrication of semiconducting oxide nanostructures by direct ink writing of readily available metal microparticles and their application as low power acetone gas sensors, Leonard Siebert, Niklas Wolff, Nicolai Ababii, Maik-Ivo Terasa, Oleg Lupan, Alexander Vahl, Viola Duppel, Haoyi Qiu, Maik Tienken, Mattia Mirabelli Victor Sontea, Franz Faupel, Lorenz Kienle, Rainer Adelung, Nano Energy, Volume 70, 2020, 104420, https://doi.org/10.1016/j.nanoen.2019.104420

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Combatting disruptive ‘noise’ in quantum communication

In a significant milestone for quantum communication technology, an experiment has demonstrated how networks can be leveraged to combat disruptive ‘noise’ in quantum communications. The international effort led by researchers…

Stretchable quantum dot display

Intrinsically stretchable quantum dot-based light-emitting diodes achieved record-breaking performance. A team of South Korean scientists led by Professor KIM Dae-Hyeong of the Center for Nanoparticle Research within the Institute for…

Internet can achieve quantum speed with light saved as sound

Researchers at the University of Copenhagen’s Niels Bohr Institute have developed a new way to create quantum memory: A small drum can store data sent with light in its sonic…