Innovation Day Laser Technology – Laser Additive Manufacturing

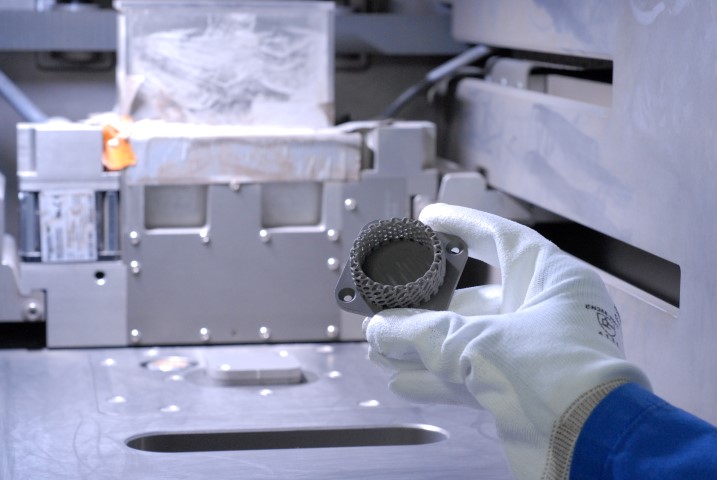

Selective laser melting makes it possible to manufacture highly complex geometries made of magnesium and magnesium alloys in a flexible and precise way. LZH

Laser technology can complement or even replace conventional processes. There is a wide range of application fields, especially for laser additive processes. This technology makes it possible to create complex geometries that cannot be manufactured with conventional production techniques, and to produce individualized parts economically even with small batch sizes.

Experts from industry and research explain the current state-of-the-art, report on the latest trends and point out relevant market developments – besides presenting application opportunities for the SMEs.

From nano to macro: laser additive manufacturing of metals and plastics

Laser additive manufacturing, however, is not only versatile in terms of application opportunities: The manufacturing scale ranges from nano to macro. And the bandwidth of materials includes both metals, such as construction steel and magnesium, but also polymers. Several live demonstrations will show how these laser-based processes work in practice.

Open dialogue between industry and research

Being an industry-oriented research institution, the LZH supports companies in implementing and optimizing laser-based processes. Not only at the Innovation Day the LZH experts are available to answer the questions of industrial users.

http://www.lzh.de/innovationstag2016 Program and registration (German language). The registration for this event is free-of-charge.

Media Contact

All latest news from the category: Event News

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…