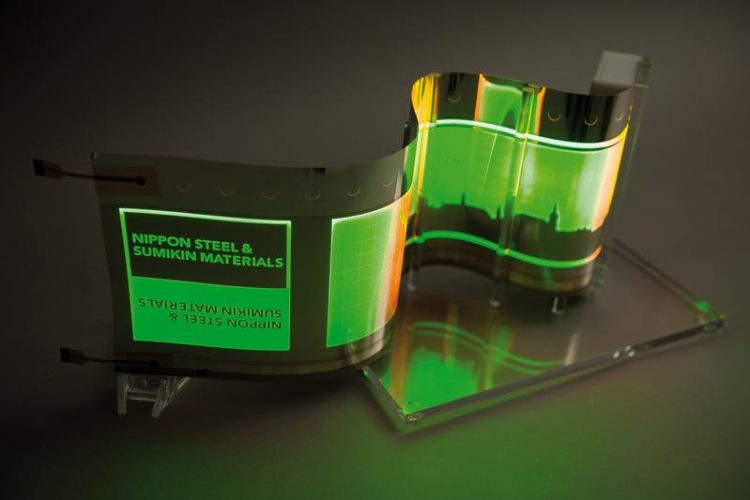

OLEDs applied to paper-thin stainless steel

OLED on stainless steel © Fraunhofer FEP, Picture in printable resolution: www.fep.fraunhofer.de/press

Stainless steel is normally associated with kitchenware and chemical Plant pipe. However, stainless steel foil has also been utilized for several years in thin-film photovoltaics and batteries. Now stainless steel can also serve as a substrate for flexible electronic components.

In comparison to the conventional substrate materials like glass or plastic web the material possesses special properties for this purpose and is well-suited as a substrate for organic light-emitting diodes (OLEDs), for example.

Thanks to the planarization layer developed by NSSMC as well as the comparatively good thermal conductivity of stainless steel, homogenous large-area lighting surfaces with current densities of more than 10 mA/cm² have become better applicable.

Moreover, OLEDs need to be protected from water vapor and oxygen in order that the organic layers remain fully functional. Stainless steel provides excellent barrier properties against environmental influences and is therefore suitable as a substrate for OLEDs from this standpoint as well.

Jun Nakatsuka, Manager of Business Development at NSMAT, is looking to the future: “Thanks to the smoothness and high thermal conductivity of the stainless steel foil we obtain extremely homogenous OLED light. We see OLEDs on stainless steel in perhaps three years from now being used in automobiles as turn indicator and back-up lights, as cladding for fascia, and as advertising displays.”

There is some ways to go before reaching that juncture. Following the expensive development of stainless steel foil, it still needs to be made suitable for production purposes. Fraunhofer FEP has at its disposal roll-to-roll processing lines for manufacturing OLEDs on flexible materials and an OLED process that has high reproducibility. This is what has made possible the development of stainless steel foil with a clean and smooth planarization layer.

Michael Stanel, Project Manager within the R2R Organic Technology department at Fraunhofer FEP explains: “In addition to machinery design and construction, we also possess comprehensive know-how in handling sensitive substrates. To be certain the stainless steel is suitable for the nanometer-thick organic layers, an R2R-compatible smoothing planarization layer was developed that is easy to integrate into the process.”

It was also important during the collaboration with NSMAT and NSSMC to work out quality standards for the future OLED fabrication. In particular, the surface properties of the substrate were specified and are being continuously improved in cooperation with NSMAT and NSSMC.

Fraunhofer FEP at aimcal 2017:

Trade Fair booth No. 22

Presentations:

Monday, October 16, 2017

Vacuum Web Coating Session

04:00 – 04:30 pm:

“Applied Research for Vacuum Web Coating: What is Coming Next?”

Dr. Nicolas Schiller, Division Director Flat and Flexible Products

Tuesday, October 17, 2017

Vacuum Web Coating Session

09:30 – 10:00am

“Vacuum-Based Roll-to-Roll OLED Coating for Pilot Scale Level”

Dr. Stefan Mogck, Group leader Roll-to-Roll Technology

Web Coating Session

10:30 – 11:00am

“Electron-Beam Curable Varnishes – Rapid Processing of Smoothing Layers on Polymer Web”

Juliane Fichtner, Division Flat and Flexible Products

Press contact:

Mrs. Annett Arnold

Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP

Phone +49 351 2586 333 | presse@fep.fraunhofer.de

Winterbergstraße 28 | 01277 Dresden | Germany | www.fep.fraunhofer.de

Media Contact

All latest news from the category: Trade Fair News

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…