Laser welding as an engine of innovation

The new technology allows to project 400 images per second and create 40 three-dimensional images per second. © Fraunhofer IOF<br>

Can lasers perform welds precisely and reliably in the midst of thundering machinery? The prototype of a new laser welder developed by an international team of researchers has now withstood the worst.

At INTEGASA and ENSA, two companies in Spain that produce heat exchangers for heavy industry, the prototype proved itself precise and reliable under the difficult conditions of routine daily use.

“Manufacturers of heat exchangers were skeptical of laser anything until now,” confirms Patrick Herwig from the Fraunhofer Institute for Material and Beam Technology IWS in Dresden. TIG-welding guns have traditionally been employed in assembly operations for welding thousands of tubes to the perforated tube sheets. This process, which is based on arc-welding technology, is very time-intensive however.

The gun must be manually inserted into every hole and removed again after welding. As a result, the fabrication process is tedious, prolonged, and expensive. European manufacturers can hardly hold their ground today against competition from countries with low labor costs. Materials researchers, software specialists, production engineers and numerous users joined forces in the EU ORBITAL Project to jointly search for a cost-effective alternative. And found one.

Engineering that meets the most demanding requirements

Instead of conventional TIG-welding guns, a laser does the job – tube sheets and tubes are welded to one another rapidly, precisely and accurately. In seconds, the tube is circumferentially welded in place and the robotic arm transporting the welding head can move on to the next hole. The welding head is designed so it anchors itself in the holes and is seated there so firmly than not even vibrations of the shop floor can disrupt the welding process.

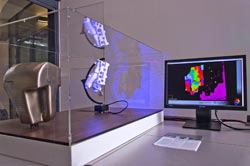

Precise guidance of the optical beam is handled by software-controlled mirrors that continuously direct it to the right location. Engineers and users from Italy, Spain, France, and Germany have been fine-tuning the process for two years. “The prototype we are exhibiting now at LASER 2013 facilitates the production of heat exchangers, and not just through its speed, but through its flexibility as well. It can even melt materials together that were considered difficult to weld until now,” according to Herwig, who was responsible for designing and testing the welding head during the EU project.

It is exactly these exotic combinations of materials that are needed by manufacturers of heat exchangers. They have to withstand extreme conditions in actual use. Heat exchangers are used in the chemical industry, ship engines, and power plants to remove heat from high-temperature, aggressive solutions of liquids. The tubing these liquids are passed through must therefore be corrosion-resistant.

However, the liquid in the tank outside the tubing that absorbs the heat is chemically inert. Cost-effective materials can be employed here. Where tank and tubing meet, differing materials must be joined. “Traditional welding techniques hit their limits here, whereas the job can be handled with the laser,” says Herwig. The researchers are confident that laser welding can be implemented so effectively in production that European companies remain competitive internationally.

Media Contact

All latest news from the category: Trade Fair News

Newest articles

Security vulnerability in browser interface

… allows computer access via graphics card. Researchers at Graz University of Technology were successful with three different side-channel attacks on graphics cards via the WebGPU browser interface. The attacks…

A closer look at mechanochemistry

Ferdi Schüth and his team at the Max Planck Institut für Kohlenforschung in Mülheim/Germany have been studying the phenomena of mechanochemistry for several years. But what actually happens at the…

Severe Vulnerabilities Discovered in Software to Protect Internet Routing

A research team from the National Research Center for Applied Cybersecurity ATHENE led by Prof. Dr. Haya Schulmann has uncovered 18 vulnerabilities in crucial software components of Resource Public Key…