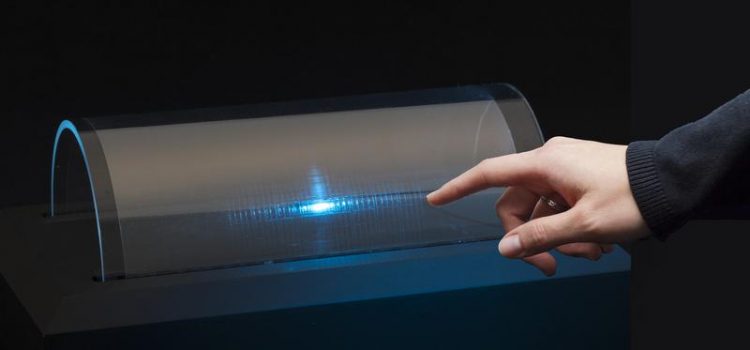

Inkjet process to print flexible touchscreens cost-efficiently

Inkjet process to print flexible touchscreens cost-efficiently. Copyright: INM

How to produce suitable coatings for those cost-efficiently will be demonstrated by INM – Leibniz-Institute for New Materials at stand B46 in hall 2 at this year's Hannover Messe as part of the leading trade fair for R & D and Technology Transfer which takes place from 25th to 29th April.

The INM will be presenting flexible touch screens, which are printed on thin plastic foils with recently developed nanoparticle inks, using transparent, conductive oxides (TCOs). These inks are suitable for a one-step printing process.

Thus transparent lines and patterns are obtained by inkjet printing or alternatively by direct gravure printing, which are electrically conductive even after bending. Thus, a one-step-printing process for cost-efficient TCO structures is enabled.

Conductive coatings with TCOs are usually applied by means of high vacuum techniques such as sputtering. For patterning of the TCO coatings additional cost-intensive process steps are necessary, for example photolithography and etching.

“We use the TCOs to produce nanoparticles with special properties,” explains Peter William de Oliveira, Head of the Optical Materials Program Division. “The TCO ink is then created by adding a solvent and a special binder to these TCO particles. The binder performs several tasks here: it not only makes the TCO nanoparticles adhere well on the substrate; it also increases the flexibility of the TCO coating: in this way, the conductivity is maintained even when the films are bent”.

The ink can be applied to the film directly by inkjet or gravure printing. After curing under UV light at low temperatures less than 130 degrees centigrade, the coating is completed.

The transparent, electronically conductive inks allow conductor tracks to be produced unproblematically even on a large scale by means of classic reel-to-reel processes. Initial trials at INM have been promising. The researchers all agree that the use of structured rollers will in the future allow large, structured conductive surfaces to be printed with a high throughput at low cost.

Your contact at the Booth:

Dr. Michael Opsölder

Jana Staudt

Your expert at INM:

Dr. Peter William de Oliveira

INM – Leibniz Institute for New Materials

Head Optical Materials

Head InnovationCenter INM

Phone: +49681-9300-148

OptiMat@leibniz-inm.de

INM conducts research and development to create new materials – for today, tomorrow and beyond. Chemists, physicists, biologists, materials scientists and engineers team up to focus on these essential questions: Which material properties are new, how can they be investigated and how can they be tailored for industrial applications in the future? Four research thrusts determine the current developments at INM: New materials for energy application, new concepts for medical surfaces, new surface materials for tribological applications and nano safety and nano bio. Research at INM is performed in three fields: Nanocomposite Technology, Interface Materials, and Bio Interfaces.

INM – Leibniz Institute for New Materials, situated in Saarbruecken, is an internationally leading centre for materials research. It is an institute of the Leibniz Association and has about 220 employees.

http://www.leibniz-inm.de/en

http://www.leibniz-gemeinschaft.de/en

Media Contact

All latest news from the category: Trade Fair News

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…