IMHP technology from DuPont can decrease cycle time during the injection moulding of semi-crystalline thermoplastics

Photo: DuPont <br>In IMHP technology (In-Mould Hold Pressure) from DuPont, hold pressure is applied using a separate mechanism integrated within the mould during the screw-dosing phase. This parallel arrangement of two injection moulding phases helps can help reduce cycle time. The actual time saving is largely determined by the degree of crystallinity of the processed material and the shot volume.<br>

In contrast to standard injection moulding procedure, the required hold pressure is applied within the mould (IMHP = In-Mould Hold Pressure). This means that the plasticising unit can already be withdrawn from the mould at the start of the hold pressure phase and, almost immediately after injection of the material, dosing of the screw can be resumed.

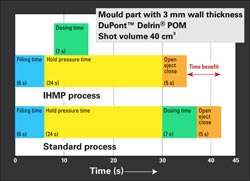

In other words, the two phases of applying hold pressure and dosing, which would traditionally follow on from each other, can now be carried out simultaneously. As a consequence the cycle time is reduced by the entire dosing time, if this is shorter than the hold pressure time, or, in the reverse case, by the entire hold pressure time. The resulting gain in time and productivity increases with dosage volume. Particularly in the case of large shot volumes or relatively short overall cycle times, the time savings can be up to 30%.

The IMHP process from DuPont offers two different methods – each integrated within the mould – for applying hold pressure and the successive feeding of molten material. As part of the first method, a hydraulically-operated piston, which is integrated in the movable side of the mould, is immersed in a specially provisioned and appropriately-dosed melt cushion. Alternatively, the equivalent melt volume is available on the stationary side of the mould in the hot runner. In this case, the molten material is pressed into the cavity using a needle-valve-like mechanism. Both methods are currently being trialled and refined by DuPont, with a current emphasis on minimising the additional space required.

“We have conducted numerous injection moulding trials with different semi-crystalline thermoplastics grades at our Technical Center in Meyrin, Switzerland, and were able to demonstrate, on the basis of producing standard bars used for tensile testing, the potential efficiency improvements,” comments Ernst A. Poppe, European manager for application and processing technology at DuPont Performance Polymers. “IMHP technology proved itself to be particularly beneficial when moulding DuPont™ Delrin® acetal resin, for which – as is the case with all grades of this particular family of thermoplastics – the hold pressure time constitutes a large proportion of its overall cycle time.

Additionally we were able to demonstrate that there were no significant changes in terms of dimensional stability and mechanical properties between standard injection-moulded samples and such produced with IMHP technology. The next step will be for us to work with moulders, hot runner and machinery producers in refining the engineering aspects of the process and thereby ensuring market entry for this time- and cost-saving technology for the moulding of semi-crystalline thermoplastics.”

DuPont Performance Polymers is committed to working with customers throughout the world to develop new products, components and systems that help reduce dependence on fossil fuels and protect people and the environment.

With more than 40 manufacturing, development and research centers throughout the world, DuPont Performance Polymers uses the industry’s broadest portfolio of plastics, elastomers, renewably sourced polymers, filaments and high-performance parts and shapes to deliver cost-effective solutions to customers in aerospace, automotive, consumer, electrical, electronic, industrial, sporting goods and other diversified industries.

DuPont (NYSE: DD) has been bringing world-class science and engineering to the global marketplace in the form of innovative products, materials, and services since 1802. The company believes that by collaborating with customers, governments, NGOs, and thought leaders we can help find solutions to such global challenges as providing enough healthy food for people everywhere, decreasing dependence on fossil fuels, and protecting life and the environment. For additional information about DuPont and its commitment to inclusive innovation, please visit www.dupont.com.

The DuPont Oval Logo, DuPont™, The miracles of science™ and all product names denoted with ® are trademarks or registered trademarks of E.I. Du Pont de Nemours and Company or its affiliates.

PP-Fakuma-2011-20

Press contact (UK, Benelux, Scandinavia)

Andrew Wilkins

Tel.: +44 (0)1353 663350

Fax: +44 (0)1353 663350

Email: dupont@plasticspr.co.uk

DuPont press contact

Rémi Daneyrole

Tel.: +41 (0)22 717 54 19

Fax: +41 (0)22 580 22 45

Media Contact

More Information:

http://www.dupont.comAll latest news from the category: Trade Fair News

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…