Fraunhofer SCAI to turn heads (& manufactured parts) at FachPack 2013 with the new PackAssistant

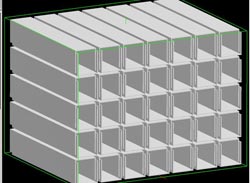

The new version of the software PackAssistant automatically turns every second part upside down. Thus, the container capacity can be increased enormously. © Fraunhofer SCAI<br>

PackAssistant is the world's leading software for optimizing packaging configurations of identical parts in standard containers. The container loading arising from the computation typically of the calculated refills typically exceeds the packing volume created by experienced packing planners.

The most important new feature of the software is that tapered components can be now packed much more closely. If, for example, several cones are packed into a container, a great deal of free space remains between the cones. If the user turns every second cone upside down, the gaps can be filled extremely well. This is what PackAssistant performs automatically in the new version. The user only needs to specify that the parts may be turned upside down.

Another new feature involves the simulation of bulk material. PackAssistant can simulate how small parts fall into a container in order to estimate the average number of components that can be stored/transported. Up to now, every component falling into the container is oriented randomly, which necessarily causes disorder in the container. However, when a container is filled in this way with long bars a great deal of space is wasted: fewer parts fit into the container than could be achieved if they were all pointing in one direction. With the new PackAssistant version, the user can specify as part of the planning calculation, whether or not the parts should be rotated. Thus, the container capacity can be increased.

The packaging type »flexible intermediate layer« now provides a greater number of packaging options for the PackAssistant user. These options differ both in the number of parts within the container and in the complexity of how the parts are arranged. Based on the 3D representation of the full container, the user can evaluate whether he wants to pack as many parts as possible in the container or if a simple arrangement with less parts is more important.

Furthermore, the new PackAssistant allows a more detailed specification of extra gaps between the containers and the packaged components. The container’s internal dimensions are reduced by the user-defined extra gaps (at the side-walls, but also at the top or bottom of the container). In this way, the insertion of additional padding, as well as production tolerances of the container geometry can be taken into account. Finally, a simplified illustration of parts can present results more speedily and generates packaging reports faster.

PackAssistant is developed by the Fraunhofer Institute SCAI together with MVI SOLVE IT GmbH. The new version of the software PackAssistant is presented at the exhibition »FachPack« in Nürnberg by the Fraunhofer SCAI distribution partner scapos AG. From 24th to 26th September, you will find PackAssistant in Hall 4, Stand 4-156.

Distribution:

scapos AG

Schloss Birlinghoven

53754 Sankt Augustin

Telephone +49 2241 14-2820,

Fax: +49 2241 14-2817

www.scapos.com/en/products/nesting-packing.html

Media Contact

All latest news from the category: Trade Fair News

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…