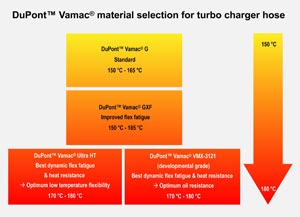

DuPont™ Vamac® Ultra HT raises the temperature bar in AEM performance for turbo hose and air ducts

Image: DuPont<br> DuPont™ Vamac® Ultra HT ethylene acrylic elastomer (AEM) offers continuous heat resistance up to 180°C, with peaks to 200°C, higher flex fatigue resistance and enhanced mechanical properties, better low temperature flexibility and superior acid resistance in blow-by gas and exhaust gas recirculation environments than standard AEM, making it an ideal candidate for automotive turbo hoses and air ducts.<br>

Vamac® Ultra HT achieves continuous heat resistance up to 180°C, with peaks to 200 °C, which, coupled with improved mechanical properties, identify it as an ideal candidate for demanding automotive applications such as turbo hoses and air ducts.

“Vamac® Ultra HT is designed to answer the need for high performance hoses in modern automotive engines, and especially to meet the demand for higher temperature resistant turbocharger hoses and ducts. Its dynamic performance and superior thermal resistance mark a further step in the development of the Vamac® product range, while processors will continue to benefit from an accommodating polymer for their formulations,” said Patrick Cazuc, Automotive Director Europe, DuPont Performance Polymers.

The latest manufacturing technology for Vamac® enables the polymerization of AEM grades with optimized structure and chemical composition, resulting in significant improvements over existing standard Vamac® elastomers.

Higher viscosity AEM grades, marketed as Vamac® Ultra, were first introduced in 2006 and became rapidly accepted by the automotive market because they provided a true step-change improvement in AEM processing, performance and customer value in applications where excellent resistance to heat, combined with exposure to engine and transmission lubricants or acids from exhaust gas recirculation and closed crankcase ventilation systems, are required.

The recent introduction of Vamac® Ultra HT has taken AEM performance a step higher in long-term heat ageing properties. A DuPont Performance Polymers study comparing ageing in air at 150 °C for 5000 hours of the most commonly used acrylic rubbers for auto hoses, demonstrated that Vamac® Ultra HT outperformed all other AEM, ACM and HT-ACM polymers tested in term of final mechanical properties such as absolute elongation and hardness change in these heat ageing conditions.

Results of the study are the subject of a paper “DuPont™ Vamac® Ultra — Latest AEM Polymers and Developments — Meeting Demands of Modern Engine Technology”, given by DuPont Performance Polymers scientist Klaus Kammerer at the International Rubber Conference during the DKT rubber event in Nuremberg, Germany, on 2-5 July, 2012 (technical paper available on request from DuPont).

Vamac® Ultra HT delivers enhanced mechanical properties at room temperature and high temperature such as hot elongation, hot tear strength and higher flex fatigue resistance, better low temperature flexibility and superior acid resistance in blow-by gas and exhaust gas recirculation environments. Its higher viscosity also improves processing versus standard AEM grades, including better green strength and scorch resistance for extrusion processes.

Vamac® Ultra HT is one of a series of new generation AEM polymers from DuPont Performance Polymers named Vamac® Ultra that help automotive OEMs meet current Euro 5 and forthcoming Euro 6 emission regulations by meeting more severe technical requirements in existing and new seals, gaskets, hoses and other underhood components. As a result, Vamac® Ultra grades are being adopted in an increasing number of commercial programmes with major auto manufacturers, including Audi, BMW, Daimler, Fiat, Ford, GM, Renault and VW.

DuPont offers more than 100 materials and product families for the global automotive industry. Through its global application development network, DuPont Automotive is committed to collaborating with customers throughout the value chain to develop new products, materials, components and systems that help reduce dependence on fossil fuels and protect people and the environment. For more information, visit automotive.dupont.com.

DuPont Performance Polymers is committed to working with customers throughout the world to develop new products, components and systems that help reduce dependence on fossil fuels and protect people and the environment. With more than 40 manufacturing, development and research centers throughout the world, DuPont Performance Polymers uses the industry’s broadest portfolio of plastics, elastomers, renewably sourced polymers, filaments and high-performance parts and shapes to deliver cost-effective solutions to customers in aerospace, automotive, consumer, electrical, electronic, industrial, sporting goods and other diversified industries.

DuPont (NYSE: DD) has been bringing world-class science and engineering to the global marketplace in the form of innovative products, materials, and services since 1802. The company believes that by collaborating with customers, governments, NGOs, and thought leaders we can help find solutions to such global challenges as providing enough healthy food for people everywhere, decreasing dependence on fossil fuels, and protecting life and the environment. For additional information about DuPont and its commitment to inclusive innovation, please visit www.dupont.com.

The DuPont Oval Logo, DuPont, The miracles of science and all product names denoted with ® are trademarks or registered trademarks of E.I. Du Pont de Nemours and Company or its affiliates.

PP-EU-dkt-2012-08

DuPont press contact

Rémi Daneyrole

Tel.: +41 (0)22 717 54 19

Fax: +41 (0)22 580 22 45

remi.daneyrole@dupont.com

Media Contact

More Information:

http://www.dupont.comAll latest news from the category: Trade Fair News

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…