Cost-effective titanium forming

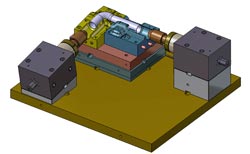

Schematic diagram depicting the forming process for titanium pipes within a process stage. <br>© Fraunhofer IWU<br>

To all intents and purposes, nothing stands in the way of titanium in terms of becoming a first-choice industrial material. It is a practically unlimited resource; it is stable and lightweight, but also extremely malleable as well as corrosion and temperature resistant.

Nevertheless, this white silver lustrous metal remains in the shadows of steel, chrome, nickel and aluminum when it comes to manufacturing. The reason for this is that efficient metal forming processes such as deep drawing or hydroforming can only be used in a very limited way. “Titanium tends to adhere to the forming tools. This leads to major damage which can cause components to fail in the worst case. This effect is amplified by the extremely high temperatures of up to 800 °C, at which titanium has to be formed“, explains André Albert, group leader for media based forming technologies at the Fraunhofer Institute for Machine Tools and Forming Technology IWU in Chemnitz, Germany.

Premiere at EuroBlech

In collaboration with his colleagues at the Fraunhofer Institute for Surface Engineering and Thin Films IST in Braunschweig, Germany, he has developed a new technology for hydroforming titanium car exhaust systems at elevated temperatures. This new method enables forming to be undertaken in a single process stage. Researchers are now presenting the initial results of the joint project at the EuroBlech trade fair (Hall 11, Booth B06) from 23 to 27 October in Hannover, Germany.

Up until now, a minimum of three stages were necessary utilizing intermediate heat treatments which partially required processing at different locations. The scientists have now developed a process and custom tool which can withstand temperatures of over 800 °C. “Forming titanium at room temperatures leads to severe cold work hardening of the processed pipe. In order to prevent cracking, the metal requires frequent treatment by means of recrystallization processes. This leads to extremely complex multi-stage forming processes which are not economically viable in large-volume production of exhaust systems. This microstructural change can be avoided at extremely high temperatures“, explains Albert.

The approximately 1.40 x 1.20 meter forming tool is manufactured from high-performance materials such as nickel-base alloys which remain stable at temperatures over 800 °C without oxidizing. A special coating, just a few micrometers thick prevents titanium from adhering to the tool, which can lead to component cracking and severe damage to the surface. Martin Weber, expert for new tribological coatings at IST says: “At temperatures from approximately 500 °C, titanium exhibits a strong tendency to combine with oxygen and nitrogen from the surrounding atmosphere. For this reason, it is necessary to work with shielding gases at extremely high temperatures, such as argon, in order to prevent oxidization of the titanium. After extensive testing with various materials, we were able to develop the ideal coating for the special conditions encountered within the various temperature ranges.“

Ideal for a broad range of applications

Titanium is extremely versatile. Approximately 40 percent of the worldwide production is used in the aerospace industry. In this sector it is used, for example, in window frames, hydraulic lines and jet engine components. Additional applications include pipes and containers for the chemicals industry, seawater-resistant components for offshore wind farms, implants, pacemakers or surgical instruments as well as consumables such as bicycle frames and items of piercing jewelry.

In the automotive industry, this versatile metal has only been used for high-end vehicles and motor sport applications up until now. However, it offers a great deal of potential, especially for mass production of exhaust systems. Due to the lack of cost-effective forming technologies for titanium, currently manifolds, exhaust pipes, catalytic converters and mufflers are primarily manufactured from high-alloy stainless steel. In doing so, titanium would not only be lighter – a total weight advantage of 40 percent can be achieved per component. It is also more available – titanium belongs to the ten most frequently occurring substances in the earth‘s crust.

Media Contact

All latest news from the category: Trade Fair News

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…