Welding thick metal sheets quickly

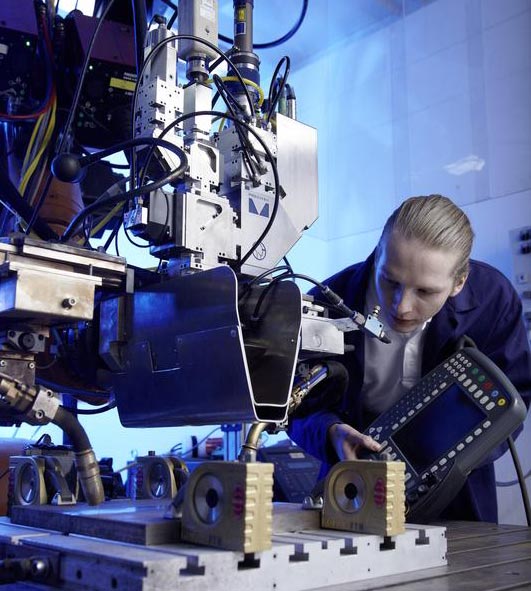

The laser-hybrid welding process combines the advantages of laser beam and GMAW welding. Photo: LZH

cientists of the Joining and Cutting of Metals Group at the LZH have developed a process that can be used to make single-sided, zero-defect welds for aluminum sheets up to a thickness of 12 mm. To do so, they have combined a laser beam with two gas metal arc welding (GMAW) torches. A scanner mirror can be used to oscillate the laser beam lengthwise or crosswise to the feed direction.

The joining process can reach feed speeds of 5 to 6 m/min, and gaps of up to 0.5 mm and edge misalignment of up to 2 mm can be bridged. The engineers have also been able to weld steel sheets with a thickness up to 23 mm at a speed of 1.5 m/mm for single layer welds.

Perfect welding seam

The innovative process is not only extremely fast: In comparison to conventional methods with multiple layer gas metal arc welding processes, the seam geometry is very narrow and filler material consumption is considerably lower. At the same time, the quality of the weld seam is very good: Welds for 12 mm thick metal sheets made of the aluminum alloy EN AW‑6082‑T6 could reach the highest evaluation group B for welding seam impurities according to DIN EN ISO 12932 and DIN EN ISO 13919‑2.

In comparison to conventional processes, a further advantage of the combined processes is reduced thermal input, and thus reduced component distortion. A solid-state disk laser with an output power of 16 kW is used for the hybrid welding process.

Twelve times faster than gas metal arc welding (GMAW)

In order to join steel sheets with a thickness of 30 mm, conventional gas metal arc welding requires a tack weld and around six filler layers. The hybrid process only needs two to three filler layers. The first layer is made using the laser-GMAW hybrid process. It also replaces the tack welds and the first four layers of the conventional gas metal arc weld. Subsequently the sheets are subject to one or two backing runs with the GMAW process. Thus, the hybrid welding process can be used to weld a component with a length of 1.5 meters in one minute, whereas conventional processes need twelve minutes.

Combining advantages and compensating disadvantages

The main advantages of hybrid welding are the synergy effects between the arc of the GMAW process and the laser beam. In the combined process, the laser is coupled into the melt pool of the filler material of the GMAW process: The filler material is melted by the arc and in the molten state it absorbs the energy of the laser beam and transfers the energy to the weld area between the sheets. The laser beam and the arc process stabilize each other, making relatively high welding speeds for arc processes possible and for high gap widths.

The joint project „HYBRILAS: Welding of thick metal sheets using brilliant laser beam sources“ was part of the „MABRILAS initiative: Material processing with brilliant laser beam sources” and was financially supported by the German Federal Ministry of Education and Research (BMBF), and supported by the Association of German Engineers (VDI-TZ).

http://www.lzh.de/en/publications/pressreleases/2014/welding-thick-metal-sheets-… Additional figure and video

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…