Coffee, Tea or Polishing Slurry?

Two UA engineering grads and a UA engineering professor have developed an environmentally friendly polishing/lapping slurry that could save millions for computer hard-drive manufacturers. They are (from left) Materials Science and Engineering (MSE) alum Don Zipperian (Pace Technologies), MSE alum John Lombardi (Ventana Research Corp.) and MSE Professor Srini Raghavan. (Photo by Erica von Koerber, Evon Photography)

The same stuff that stains your coffee mug could reduce pollution in the computer hard-drive industry, while saving drive makers millions of dollars in manufacturing costs.

The compound is derived from the tannin phytochemicals commonly found in plants. Green tea has a lot of them.

John Lombardi, president of Tucson-based Ventana Research Corp. combined phytochemicals from green-tea extract, synthetic proteins and an abrasive to produce a lapping slurry that is three to four times faster at polishing magneto-resistive heads than the ones currently in use. An added bonus — one that could save millions of dollars for hard-drive manufacturers — is that it’s also environmentally friendly, unlike many of the solvent-based slurries now used.

Lombardi, who earned his master’s (1994) and Ph.D. (1996) degrees from UA in Materials Science and Engineering (MSE), admitted that green tea isn’t intuitively obvious as a key ingredient in lapping slurries. He made the link after looking at the compounds that allow barnacles to cling tenaciously to ship hulls. These compounds have a chemical structure that is similar to that found in tannin phytochemicals. “This led me to start looking at various tannin phytochemical compounds as a general class of chemicals,” he said.

“There are probably thousands of these chemicals in nature,” Lombardi added. “We’re using green tea because it has a high percentage of phytochemicals.”

UA MSE Professor Srini Raghavan has been working with Lombardi to test the green-tea compound as a slurry additive and is conducting basic science experiments to find out why it works so well.

A third team member, Don Zipperian, of Pace Technologies, is providing the industry perspective by determining precisely which slurry attributes are most valuable to hard-drive manufacturers. He also will be heavily involved in marketing the Ventana slurry. Pace Technologies is a Tucson-based company that sells products for micro-surface finishing.

The ceramic debris particles scrubbed away during hard-drive head polishing are submicron-size (less than a millionth of a meter in diameter) and cling to the surface, making them difficult to remove. Tannin phytochemicals have a strong affinity for these tiny particles, tightly bind to them and give them an electrostatic charge, which causes the particles to be repelled from other particles and the head surface. This makes them float so they can be easily washed away with water.

“The tannin phytochemicals play a dual role by increasing the polishing rate and enhancing the removal of particles produced by the polishing process,” Raghavan explained.

Lombardi noted that the computer industry produces more than 161 million hard drives annually, with read-write heads that must have no imperfections larger than 10 angstroms. That’s tiny. The average human hair has a diameter of about 75,000 angstroms.

Polishing with this kind of precision isn’t easy. Zipperian, who earned his Ph.D. from UA MSE in 1987, compared the polishing process to flying a 747 at full throttle a few inches off the ground. Zipperian is chief technical officer for Pace Technologies, whose customers include semiconductor, hard-drive, and fiber-optics manufacturers, as well as companies in the metallographic industry that test materials, including metals, ceramics and plastics.

He said hard-drive manufactures incur significant disposal costs from the industrial solvents currently used for polishing read-write heads.

“As far as we know, all the chemicals we’re using should be biodegradable,” Lombardi added. “Most of the chemicals and reactants we use are shipped in foil-lined bags and there are no materials-handling problems involved.” Switching to these biodegradable chemicals could save manufacturers millions of dollars in disposal costs.

Ventana Research Corp. formulates specialty compounds, and now is looking at other applications for tannin phytochemicals. Their high affinity for metals and ceramics could lead to applications in mining, cancer treatment, high performance adhesives, specialty coatings, removal of metal contaminants from water, and wastewater treatment.

Lombardi, Raghavan and Zipperian developed the lapping/polishing slurries through a National Science Foundation (NSF) Small Business Innovation Research (SBIR) grant.

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

A cause of immunodeficiency identified

After stroke and heart attack: Every year, between 250,000 and 300,000 people in Germany suffer from a stroke or heart attack. These patients suffer immune disturbances and are very frequently…

Wildfire danger to increase due to climate change

WSL Institute for Snow and Avalanche Research (SLF) researchers expect an elevated wildfire danger in the Alpine Foreland from 2040 onwards due to changing meteorological conditions. The danger currently remains…

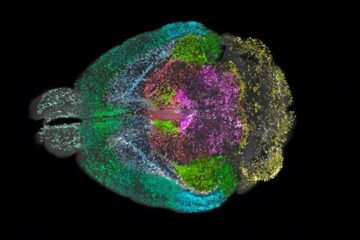

Advanced Brain Science Without Coding Expertise

Researchers at Helmholtz Munich and the LMU University Hospital Munich introduce DELiVR, offering a new AI-based approach to the complex task of brain cell mapping. The deep learning tool democratizes…