NIST study helps auto engineers by the numbers

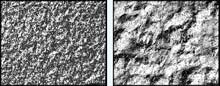

These optical micrographs show two surfaces with the same average roughness values but dramatically different surface topographies. <br>

Using rigorous statistical analysis, National Institute of Standards and Technology (NIST) researchers identified a potential source of error in the surface roughness data used in the automotive industry to predict how friction affects production of metal parts during forming.

With this improved analysis, automakers should be able to more easily incorporate lighter weight materials in their products and improve fuel efficiency.

The NIST scientists presented their findings at the Society of Automotive Engineers’ World Congress 2004, held in Detroit March 8-11.

The NIST researchers found industry often tries to draw specific conclusions about the surface with mathematically averaged roughness data that are too general.

They also demonstrated that the current industrial practice for interpreting surface roughness may produce the same roughness values for two surfaces with markedly different topographies. This could lead to inaccurate predictions of friction because this surface roughness measurement only quantifies the average peak heights and valley depths, not the spacing between them.

Friction is key in auto part production. Too little friction during manufacturing leads to parts wrinkling and buckling. Too much friction can cause parts to tear.

The NIST team is continuing its work and is developing a new analytical approach for industry use for more reliable predictions of surface roughness and friction.

Media Contact

More Information:

http://www.nist.gov/All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…

Innovative microscopy demystifies metabolism of Alzheimer’s

Researchers at UC San Diego have deployed state-of-the art imaging techniques to discover the metabolism driving Alzheimer’s disease; results suggest new treatment strategies. Alzheimer’s disease causes significant problems with memory,…

A cause of immunodeficiency identified

After stroke and heart attack: Every year, between 250,000 and 300,000 people in Germany suffer from a stroke or heart attack. These patients suffer immune disturbances and are very frequently…