Radio waves help see moisture inside walls

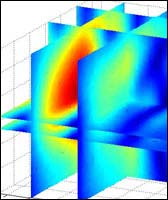

Three-dimensional perspective view of a mocked-up wall section. Red circular area at left indicates moisture inside a wall

The building community soon may have radio vision—a new way to “see” moisture inside walls. Building researchers at the National Institute of Standards and Technology (NIST) have joined forces with Intelligent Automation Inc. in Rockville, Md., to develop a way to use ultra wide-band radio waves to non-destructively detect moisture within the walls of a building. As any homeowner who’s suffered with leaky plumbing or mold problems will tell you, the current state of the art for pinpointing moisture problem areas relies mostly on guesswork and a drywall saw.

Based on hardware developed by Intelligent Automation, the new NIST technique involves sending a broad range of radio frequencies through typical drywall construction to look for a “moisture” signature in the signal that is reflected back. Laboratory experiments conducted with a simplified wall section made of gypsum board, fiberglass insulation, and oriented strand board (similar to plywood), demonstrated that the new method can locate moisture pockets to within one centimeter.

The presence of water within the model wall produced a stronger reflection of radio waves at specific frequencies. The elapsed time between transmission of the waves and their arrival at a receiving antenna helps determine the location of the water. By processing the reflected signals with computer software, the researchers can create detailed three-dimensional maps that highlight wet areas.

Research is continuing to see how well the apparatus performs with real walls that include studs, wires, pipes and windows that may complicate the readings. A paper describing the research has been accepted for publication in an upcoming issue of ASHRAE Transactions.

Media Contact

More Information:

http://www.nist.gov/All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…