Nano-optics: Getting the most out of tiny lasers

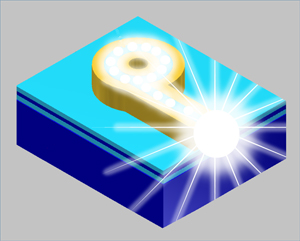

Computer simulations show that efficient light extraction from a nanoring plasmonic laser can occur when a waveguide is connected flush with one edge of the device. Modified from Ref. 1 and licensed under CC BY-NC 3.0 Copyright : 2014 C. Lee et al.

Semiconductor optical devices are becoming increasingly commonplace. For example, light-emitting diodes, as they become more power efficient, are rapidly replacing conventional light bulbs. Lasers too are now found in every barcode scanner and compact-disc reader.

When designing these devices, a crucial consideration is how best to get the light generated within the solid material out into the real world. Chee-Wei Lee at the A*STAR Data Storage Institute, Singapore, and international colleagues have now proposed a light-extraction scheme that is capable of transferring over half the light created by a submicrometer-scale laser into a waveguide(1).

Plasmonic lasers are the smallest lasers created to date — they can even be smaller than the wavelength of the light they emit. This counterintuitive property results from plasmons, which are hybrid electron–light particles created by coupling light with electrons in a metal.

Lee and his team considered the simplest plasmonic laser: a ring of a light-emitting semiconductor coated with a thin silver layer. Light can travel round and round inside the ring, which provides the optical cavity required in most laser devices.

What is more, this tiny laser can be bonded onto a silicon substrate to make it compatible with compact photonics-on-a-chip technology. Lee and his team used computer simulations to demonstrate that high extraction efficiency is obtained when a waveguide (a light-carrying submicrometer-wide semiconductor strip) is directly connected to the side of the laser.

The team used a numerical simulation technique called finite-difference time-domain to study the performance of waveguides of different widths connected at different points on the laser. Their models revealed that the optimal structure is an asymmetric one.

When the extraction waveguide is displaced from the center of the ring — so that the waveguide is flush with the edge of the cavity — it produces a peak out-coupling efficiency of 56 per cent (see image). “Our scheme, based on directly joining a waveguide, enhances light extraction by splitting the plasmon mode,” explains Lee.

Scientists have previously extracted light from plasmonic lasers by running a waveguide extremely close to, but not touching, the cavity ring. Light can leak across the gap between the laser and the waveguide through an effect called evanescent coupling.

But this approach requires precise control over the gap size and the optical properties of the material in the gap. The method developed by the team, however, can be implemented using much simpler device fabrication. “We are now in the process of actually realizing such a device,” says Lee.

Reference

1. Lee, C.-W., Singh, G. & Wang, Q. Light extraction — a practical consideration for a plasmonic nano-ring laser. Nanoscale 5, 10835–10838 (2013).

Associated links

Media Contact

More Information:

http://www.researchsea.comAll latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

“Nanostitches” enable lighter and tougher composite materials

In research that may lead to next-generation airplanes and spacecraft, MIT engineers used carbon nanotubes to prevent cracking in multilayered composites. To save on fuel and reduce aircraft emissions, engineers…

Trash to treasure

Researchers turn metal waste into catalyst for hydrogen. Scientists have found a way to transform metal waste into a highly efficient catalyst to make hydrogen from water, a discovery that…

Real-time detection of infectious disease viruses

… by searching for molecular fingerprinting. A research team consisting of Professor Kyoung-Duck Park and Taeyoung Moon and Huitae Joo, PhD candidates, from the Department of Physics at Pohang University…