Joining ultra-high-strength chromium steels reliably with laser technology

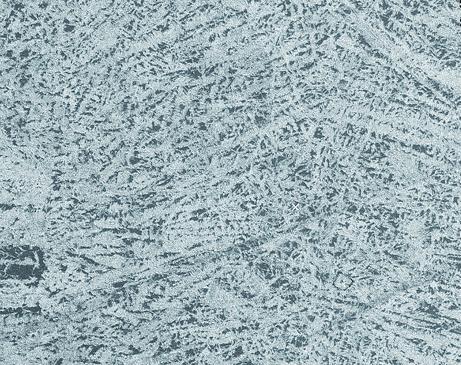

Microstructure of weld in 1.4034. Picture Source: Fraunhofer ILT, Aachen, Germany.

Within the scope of the research project SECOMAL, the Fraunhofer Institute for Laser Technology ILT in Aachen has determined process parameters and process windows for the laser welding of three ultra-high-strength chromium steels: pure ferritic, ferritic-martensitic, and pure martensitic with carbon content ranging from 0.02 to 0.46 mass percent. Hardened, they achieve a tensile strength of up to two gigapascals with fracture strain of 10 percent. Their inherent resistance to corrosion makes these steels ideal for vehicle manufacturing.

The materials with the lowest and the highest carbon content – ferritic and martensitic chromium steels, respectively – can now be easily joined, even when the materials are hardened. “Only the martensitic stainless grade 1.4021, with an average carbon content of 0.21 percent poses dfficulties,” says Dipl.-Ing. Martin Dahmen, a researcher of the Fraunhofer ILT.

According to the textbook, preheating martensitic steel is recommended before joining and then tempering it – that is, heating the welding zone locally – to improve the toughness in the heat-affected zone. Hardened sheets can be tempered up to 450°C without causing any loss of quality. In principle, all types of laser beams are suitable for welding materials, but since the laser should produce parallel seam edges, Dahmen recommends using only the so-called brilliant beam sources and CO2 lasers.

But how does the laser compare to metal active gas (MAG) welding? “With judicious heat treatment, the hardened chromium steel can be joined without difficulty, with the exception of 1.4021,” says the ILT researcher. “On the other hand, MAG welding is problematic because of the resulting high-energy input in the joining areas, even with appropriate heat treatment.”

What successful laser welding looks like in practice will be showcased by the Fraunhofer ILT on its test specimen of a B-pillar of ultra high-strength steel welded to a vehicle rocker panel. “This proves that welding ultra high-strength materials by laser offers a viable alternative to manganese boron steels,” says Dahmen. Visitors to EuroBLECH 2014 can visit the demonstrator exhibit and learn more about laser welding chromium steels and other Fraunhofer ILT projects at the Fraunhofer Joint Stand in Hall 11, Booth C05.

SECOMAL joint research project

The focus of this research project is investigating how laser and MAG welding can be used for fusion welding ultra-high-strength stainless steels with a martensitic structure. SECOMAL is a collaborative research project of the Fraunhofer ILT and the Paderborn University Laboratory of Materials and Joining Technology (LWF), the Fraunhofer Institute for Structural Durability and System Reliability LBF, and the steelmaker Outokumpu Nirosta. It is funded by the German Federal Ministry for Economic Affairs and Energy (BMWi), the German Federation of Industrial Research Associations Otto von Guericke e.V. (AiF), and the Research Association for Steel Application (FOSTA).

Contact

Dipl.-Ing. Martin Dahmen

Macro Joining and Cutting Group

Telephone +49 241 8906-307

martin.dahmen@ilt.fraunhofer.de

Dr. Dirk Petring

Leader Macro Joining and Cutting Group

Telephone +49 241 8906-210

dirk.petring@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT

Steinbachstraße 15

52074 Aachen, Germany

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…