Infrared Testing Equipment for Demanding Heating Processes

Vacuum test equipment for long term testing with infrared emitters<br><br>Copyright Heraeus Noblelight 2012<br>

Vacuum processes also offer some advantages in the coating of glass or metals, for example in preventing unwanted oxidation processes.

Many of these processes require high energy, precisely controllable heating sources. This is where quartz glass infrared emitters offers a number of advantages. They transfer heat without contact and at high output and they also respond very quickly to control signals.

However, the use of infrared processes under vacuum conditions is not as simple as it sounds. Reflection within a closed chamber can sometimes significantly affect the heat distribution. Many parameters must be taken into consideration in the equipment design, in order that the heat is effective precisely where it is needed.

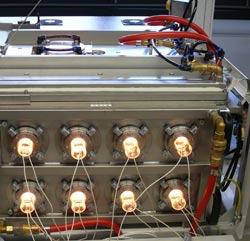

With its newly introduced vacuum testing equipment, Heraeus Noblelight can carry out tests on heating processes in automated long term operation under load conditions relating as closely as possible to those found in practice.

Many innovative products such as semi-conductors, solar cells and modern glass- and metal coatings require heating processes with special properties during their manufacture or treatment. Chip slices, discs and work pieces are processed at very high temperatures under vacuum conditions. In order to do this, extremely high heating energy has to be precisely targeted and transferred energy-efficiently. At the same time the vacuum, the high surrounding temperature or aggressive media act on the heat source.

Heraeus has now expanded its vacuum test chamber at its in-house Applications Centre with the introduction of advanced technology vacuum test equipment. With this, as well as single tests, automated long term tests can be carried out over long periods. Under the kind of loading met in practice, plant incorporating infrared heating processes can be designed cost-effectively and energy-efficiently and maintenance intervals realistically projected.

Continuous pressures up to 10-6 mbar can be generated with the vacuum test equipment and, dependent on customer specification, shortwave infrared emitters or medium wave Carbon Infrared emitters can be selected. Consequently, a wide range of emitters can be varied, in arrangement and in number. The infrared emitters heat the materials either directly in the chamber or they can be decoupled from the process area by means of a quartz glass sheathing tube. If a sheathing tube is used emitters can easily be replaced from outside. The tests are computer logged and recorded and evaluated with the customer.

“We have quickly established that the environmental conditions have a great effect on the efficiency of the infrared process,” says Martin Klinecky, Vacuum Applications Specialist at Heraeus. “Currently, the equipment is helping us to carry out further development work on our infrared emitters for the energy-saving manufacture of efficient solar cells.”

Under vacuum conditions, some materials heat up more quickly, water evaporates at lower temperatures and geometrically complicated products can be dried better. The color and type of the material and the color and thickness of the coating, as well as the required temperature and drying time also affect the heating process design. When confronted with new materials and innovative coating, it is more than worthwhile to carry out trials so that the facility or plant can be designed in the most energy-efficient way possible.

The optimum heat distribution can be simulated in advance using modern numeric methods such as Computer Aided Engineering (CAE). The vacuum test facility helps to verify or endorse the results predicted by the computer simulation.

Heraeus, the precious metals and technology group headquartered in Hanau, Germany, is a global, private company with more than 160 years of tradition. Our fields of competence include precious metals, materials, and technologies, sensors, biomaterials, and medical products, as well as dental products, quartz glass, and specialty light sources. With product revenues of €4.8 billion and precious metal trading revenues of €21.3 billion, as well as more than 13,300 employees in over 120 subsidiaries worldwide, Heraeus holds a leading position in its global markets.

Heraeus Noblelight GmbH with its headquarters in Hanau and with subsidiaries in the USA, Great Britain, France, China and Australia, is one of the technology- and market-leaders in the production of specialist light sources. In 2011, Heraeus Noblelight had an annual turnover of 103 Million € and employed 731 people worldwide. The organization develops, manufactures and markets infrared and ultraviolet emitters for applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical measurement techniques.

For further information please contact:

Technical:

Heraeus Noblelight GmbH

Reinhard-Heraeus-Ring 7

D-63801 Kleinostheim

Tel +49 6181/35-8545, Fax +49 6181/35-16 8545

E-Mail hng-infrared@heraeus.com

Press:

Dr. Marie-Luise Bopp

Heraeus Noblelight GmbH,

Tel +49 6181/35-8547, Fax +49 6181/35-16 8547

E-Mail marie-luise.bopp@heraeus.com

Media Contact

More Information:

http://www.heraeus-noblelight.com/infraredAll latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…