Fabrication method can affect the use of block copolymer thin films

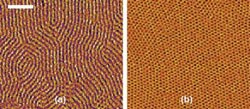

The method of creating a thin film can have great effect on the material, such as the orientation of the tiny cylinders in this film proposed for use in computer memory. One method of film creation is far more effective at creating copolymer films with cylinders that stand on end (b), as they must to be usable. Scale bar represents 200 nanometers. Credit: NIST<br>

The results* suggest that deeper work is necessary to explore the best way of creating these films, which are used in applications ranging from high-tech mirrors to computer memory devices.

Thin films spread atop a surface have many applications in industry. Inexpensive organic solar cells might be made of such films, to name one potential use. Typically they're made by dissolving the polymer, and then spreading a small amount of the liquid out on a surface, called a substrate. The solution becomes a film as the solvent dries and the remainder solidifies. But as this happens, stresses develop within the film that can affect its structure.

Manufacturers would like to know more about how to control these stresses to ensure the film does what they want. But scientists who study film formation often use a different method of casting films than a manufacturer would. One method used in industry is “flow coating”—similar to spreading frosting across a cake. Another method is “spin casting”—placing a drop of liquid on a substrate that spins rapidly and spreads the droplet out evenly by centrifugal force. Both methods create smooth films generally, but the team decided to examine whether the two methods create different effects in finished films consisting of a self-assembling block copolymer.

“It's an important question because some proposed applications intend to take advantage of these effects,” Douglas says.

The team's comparison led to results that surprised them. Although the rapid spinning of spin casting is very dynamic, suggesting it would convey more stress to the resulting film, it actually led to fewer residual stresses than flow coating did. As previous studies have shown that leftover solvent can lead to stresses in the film, the team's new theory is that because the solvent evaporates from the developing film more slowly in flow coating, this solvent discourages the film solids from arranging themselves into the equilibrium structure.

For one example, the practical benefits of this understanding could help manufacturers who propose making computer memory devices from thin films in which the solids arrange themselves as tiny cylinders in the film. Such devices would require the cylinders to stand on end, not lay down flat.

“We find we can get them to stand up much more easily with one casting method than another,” Douglas says. “If we can get better results simply by varying the mode of film casting, we need to explore more deeply what happens when you make films by different methods.”

* X. Zhang, J.F. Douglas and R.L. Jones. Influence of film casting method on block copolymer ordering in thin films. Soft Matter, Mar. 21, 2012. doi:10.1039/C2SM07308K.

Media Contact

More Information:

http://www.nist.govAll latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…