Edge-rounding and removing burrs of glass parts with laser radiation

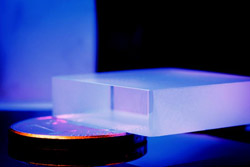

Part made of quartz glass, laser-polished and edge-rounded.<br><br>Picture Source: Fraunhofer ILT / Volker Lannert, Aachen<br>

It can be used not only for polishing surfaces, but also for rounding edges and for removing burrs e.g. split lines on parts formed by injection or compression molding. At the 2012 glasstec international trade fair, which will take place in Düsseldorf from October 23 to 26, experts from Fraunhofer ILT will be explaining the process and displaying samples of glass parts whose edges were rounded with CO2 laser radiation.

The stability of glass parts can be significantly increased by rounding their edges. Laser polishing is an economical and fast technique for edge-rounding of glass parts. When, as in laser polishing, a glass edge is processed with a CO2 laser, the material at the outermost surface layer heats up due to the surface near absorption of 80 percent of the laser radiation. A temperature just below its evaporation temperature is reached in the outher surface. This greatly decreases the viscosity of the material, while surface tension reduces the surface roughness. In contrast to conventional polishing techniques, no material is removed from the surface with laser polishing.

In addition, the surface of the edge is polished. Subsequently, the edge surface and adjacent areas exhibit a very low level of micro-roughness. The result is not only greater stability in the edge region, but also a noticeable increase in the gloss level of the processed area.

“You can set the degree to which the edge is to be rounded and polished by means of the process temperature in the surface near layer,” explains Annika Richmann, project manager at Fraunhofer ILT. “Although parts are usually processed using a beam diameter of several millimeters, very local processing is also possible. Laser polishing can be used on virtually all types of glass, with greater process speeds obtainable for low-melting glasses.”

Bid farewell to tangible and visible burrs

The technique is also suited to removing burrs on glass and plastic injection and compression-molded parts. As in laser polishing, material is redistributed rather than removed; burrs are diminished to the point where they can no longer be seen or felt. This technique also greatly reduces the micro-roughness of the processed areas and heightens gloss.

Polishing freeform optics

Research at Fraunhofer ILT is presently focused on applying laser polishing techniques to freeform optics, where conventional polishing techniques are very slow. Lasers shorten processing times by a factor of up to 100, depending on the surface geometry to be polished. For many applications – including optical systems for illumination optics – the roughness values now obtainable are more than adequate. The challenge for the experts charged with further developing the laser polishing technique now consists in also attaining adequate roughness for imaging optics by means of further increasing shape accuracy and reducing waviness.

For further information

Dipl.-Phys. Annika Richmann

Group Polishing

Phone +49 241 8906-282

annika.richmann@ilt.fraunhofer.de

Dr. Edgar Willenborg

Head of the Group Polishing

Phone +49 241 8906-213

edgar.willenborg@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT

Steinbachstr. 15, 52074 Aachen, Germany

Media Contact

More Information:

http://www.ilt.fraunhofer.deAll latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

“Nanostitches” enable lighter and tougher composite materials

In research that may lead to next-generation airplanes and spacecraft, MIT engineers used carbon nanotubes to prevent cracking in multilayered composites. To save on fuel and reduce aircraft emissions, engineers…

Trash to treasure

Researchers turn metal waste into catalyst for hydrogen. Scientists have found a way to transform metal waste into a highly efficient catalyst to make hydrogen from water, a discovery that…

Real-time detection of infectious disease viruses

… by searching for molecular fingerprinting. A research team consisting of Professor Kyoung-Duck Park and Taeyoung Moon and Huitae Joo, PhD candidates, from the Department of Physics at Pohang University…