The world's sharpest X-ray beam shines at DESY

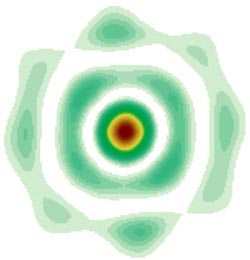

This is the reconstruction of the two-dimensional focus field. The intensity is color coded.<br><br>Credit: Image: University of Göttingen<br>

The world's sharpest X-ray beam shines at DESY. At the X-ray light source PETRA III, scientists from Göttingen generated a beam with a diameter of barely 5 nanometres – this is ten thousand times thinner than a human hair. This fine beam of X-ray light allows focusing on smallest details.

The research groups of Professor Tim Salditt from the Institute of X-ray Physics and of Professor Hans-Ulrich Krebs from the Institute of Materials Physics of the University of Göttingen published their work in the research journal Optics Express.

High-energy (hard) X-ray light cannot be focused as easily as visible light by using a burning glass. “Instead of a common lens, we use a so-called Fresnel lens which consists of several layers,” explains co-author Dr. Markus Osterhoff. The central support is a fine tungsten wire with the thickness of only a thousandth of a millimetre. Around the wire, nanometre-thin silicon and tungsten layers are applied in an alternating way.

The physicists then cut a thin slice from the coated wire. “This slice has 50 to 60 silicon and tungsten layers, comparable to growth rings of a tree,” explains team member Florian Döring. “And the layer thicknesses have to be extremely precise,” adds Christian Eberl. The two PhD students have optimized the different fabrication steps.

The wire slice with a size of only about two thousandths of a millimetre is used as a lens. However, it does not diffract light like a glass lens but scatters it like an optical grid generating a pattern of bright and dark patches. In this case, the thickness of the layers is selected in such a way that the bright areas of the diffraction pattern coincide at the same spot.

The more precise the lens is fabricated, the sharper becomes the X-ray focus. With this method, the physicists obtained an X-ray beam of 4.3 nanometres (millionth of a millimetre) diameter in horizontal direction and 4.7 nanometres diameter in vertical direction. Until recently it was even debated whether fundamental limits of X-ray optics would stand against such small focal widths. The outstanding brilliance of DESY's X-ray light source PETRA III helped to make a usable nano focus possible.

The fine X-ray beam opens up new possibilities for materials science, e.g. the investigation of nano wires to be used in solar cells. “Usually, when investigating the chemical composition of a sample, the beam size limits the sharpness of the image. Before this experiment, this limit was at about 20 nanometers”, said DESY researcher Dr. Michael Sprung, responsible scientist for the PETRA measuring station P10, where the experiments are carried out.

As a next step, the scientists want to improve the performance by depositing the layers on ultrathin and extremely uniform glass fibres. Moreover, they plan to scan first nanoscopic structures with their novel ultra-sharp beam. In the future, such a lens should help to create foci of ultimate flux density with free-electron laser (FEL) radiation.

Media Contact

More Information:

http://www.desy.deAll latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

“Nanostitches” enable lighter and tougher composite materials

In research that may lead to next-generation airplanes and spacecraft, MIT engineers used carbon nanotubes to prevent cracking in multilayered composites. To save on fuel and reduce aircraft emissions, engineers…

Trash to treasure

Researchers turn metal waste into catalyst for hydrogen. Scientists have found a way to transform metal waste into a highly efficient catalyst to make hydrogen from water, a discovery that…

Real-time detection of infectious disease viruses

… by searching for molecular fingerprinting. A research team consisting of Professor Kyoung-Duck Park and Taeyoung Moon and Huitae Joo, PhD candidates, from the Department of Physics at Pohang University…