Supercomputer unravels structures in DVD materials

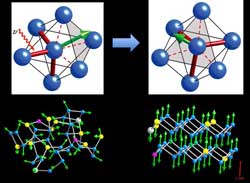

Model of crystallization of AIST alloy in a DVD. <br>Upper left: a laser pulse (hv arrow) causes motion of the central antimony atom (left), which then exchanges its bonds to two neighbours. <br>Upper right: The green vector sum of the three short red bonds changes. <br>Below: A sequence of such processes leads from the amorphous (left) to the crystalline form (right). Illustration: Forschungszentrum Jülich<br>

Although the storage of films and music on a DVD is part of our digital world, the physical basis of the storage mechanism is not understood in detail. In the current issue of the leading journal Nature Materials, researchers from Jülich, Finland, and Japan provide insight into the read and write processes in a DVD. This knowledge should enable improved storage materials to be developed. (DOI: 10.1038/NMAT2931)

Information is stored in a DVD in the form of microscopic bits (each less than 100 nanometres in size) in a thin layer of a polycrystalline alloy containing several elements. The bits can have a disordered, amorphous or an ordered, crystalline structure. The transition between the two phases lasts only a few nanoseconds and can be triggered by a laser pulse. Common alloys for storage materials such as DVD-RAMs or Blu-ray Discs contain germanium (Ge), antimony (Sb) und tellurium (Te) and are known as GST after the initials of the elements. The most popular alloys for DVD-RW are AIST alloys, which contain small amounts of silver (Ag) and indium (In) as well as antimony (Sb) and tellurium (Te).

“Both alloy families contain antimony and tellurium and appear to have much in common, but the phase change mechanisms are quite different”, explains Dr. Robert Jones of Forschungszentrum Jülich, who has collaborated with an international team on the problem. In addition to experimental data and x-ray spectra from the Japanese synchrotron SPring-8, the world's most powerful x-ray source, the team used extensive simulations on the Jülich supercomputer JUGENE. The combination of experiment and simulations has enabled the structures of both phases to be determined for the first time and allowed the development of a model to explain the rapid phase change.

The phase change in AIST alloys proceeds from the outside of the bit, where it adjoins the crystalline surroundings, towards its interior. In Nature Materials, the team explains this using a “bond exchange model”, where the local environment in the amorphous bit is changed by small movements of an antimony atom (see figure). A sequence of many such steps results in reorientation (crystallization), without requiring empty regions or large motions. The antimony atoms, stimulated by the laser pulse, have simply exchanged the strengths of the bonds to two neighbours, hence the name „bond exchange” model.

The team had clarified the phase transition in GST materials in earlier work (DOI: 10.1103/PhysRevB.80.020201). Here the amorphous bit crystallizes via nucleation, i.e. small crystallites formed in the interior grow rapidly until they covered the whole bit. The speed of the transition can be explained by observing that amorphous and crystalline phases contain the same structural units, “„ABAB” rings. These four-membered rings contain two germanium or antimony atoms (A) and two tellurium atoms (B) and can rearrange in the available empty space without breaking many atomic bonds.

The calculation of the structure of amorphous AIST is the largest yet performed in this area of research, with simulations of 640 atoms over the comparatively long time of several hundred picoseconds. Some 4000 processors of the Jülich supercomputer JUGENE were used for over four months in order to obtain the necessary precision. In addition to sheer computing power, however, experience in scientific computing and the simulation of condensed matter is essential. Jones notes: “Forschungszentrum Jülich is one of the few places where all these aspects come together.”

The deeper theoretical understanding of the processes involved in writing and erasing a DVD should aid the development of phase change storage media with longer life, larger capacity, or shorter access times.

More information on Jülich solid-state research

http://www.fz-juelich.de/iff/

Homepage of Nature Materials:

http://www.nature.com/nmat/index.html

Further information on the topic at:

http://www.fz-juelich.de/portal/index.php?cmd=show&mid=715&index=163

Contact:

Dr. Robert Jones

Tel.: +49 2461 61-4202

r.jones@fz-juelich.de

Press contact:

Kosta Schinarakis

Tel.: +49 2461 614771

k.schinarakis@fz-juelich.de

Forschungszentrum Jülich…

pursues cutting-edge interdisciplinary research addressing pressing issues facing society today while at the same time developing key technologies for tomorrow. Research focuses on the areas of health, energy and environment, and information technology. The cooperation of the researchers at Jülich is characterized by outstanding expertise and infrastructure in physics, materials science, nanotechnology, and supercomputing. With a staff of about 4 600, Jülich – a member of the Helmholtz Association – is one of the largest research centres in Europe.

Media Contact

More Information:

http://www.fz-juelich.deAll latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…