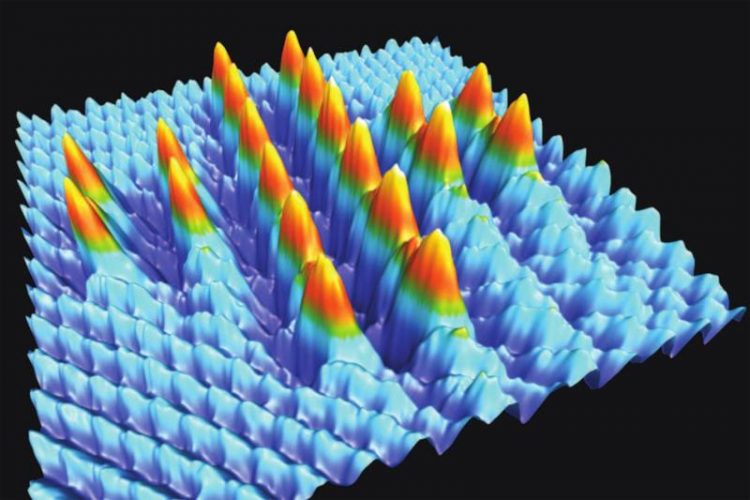

Smallest Swiss Cross – Made of 20 Single Atoms

20 bromine atoms positioned on a sodium chloride surface using the tip of an atomic force microscope at room temperature, creating a Swiss cross with the size of 5.6nm. Department of Physics, University of Basel

Together with teams from Finland and Japan, physicists from the University of Basel were able to place 20 single atoms on a fully insulated surface at room temperature to form the smallest “Swiss cross”, thus taking a big step towards next generation atomic-scale storage devices. The academic journal Nature Communications has published their results.

Ever since the 1990s, physicists have been able to directly control surface structures by moving and positioning single atoms to certain atomic sites. A number of atomic manipulations have previously been demonstrated both on conducting or semi-conducting surfaces mainly under very low temperatures.

However, the fabrication of artificial structures on an insulator at room temperature is still a long-standing challenge and previous attempts were uncontrollable and did not deliver the desired results.

In this study, an international team of researchers around Shigeki Kawai and Ernst Meyer from the Department of Physics at the University of Basel presents the first successful systematic atomic manipulation on an insulating surface at room temperatures.

Using the tip of an atomic force microscope, they placed single bromine atoms on a sodium chloride surface to construct the shape of the Swiss cross. The tiny cross is made of 20 bromine atoms and was created by exchanging chlorine with bromine atoms. It measures only 5.6 nanometers square and represents the largest number of atomic manipulations ever achieved at room temperature.

New storage devices

Together with theoretical calculations the scientists were able to identify the novel manipulation mechanisms to fabricate unique structures at the atomic scale. The study thus shows how systematic atomic manipulation at room temperature is now possible and represents an important step towards the fabrication of a new generation of electromechanical systems, advanced atomic-scale data storage devices and logic circuits.

Original source:

Shigeki Kawai, Adam S. Foster, Filippo Federici Canova, Hiroshi Onodera, Shin-ichi Kitamura, and Ernst Meyer

Atom manipulation on an insulating surface at room temperature

Nature Communications | doi: 10.1038/ncomms5403

Further information:

Prof. Ernst Meyer, Department of Physics, University of Basel, phone: +41 61 267 37 24, email: ernst.meyer@unibas.ch

Media Contact

More Information:

http://www.unibas.chAll latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…