Record-breaking detector may aid nuclear inspections

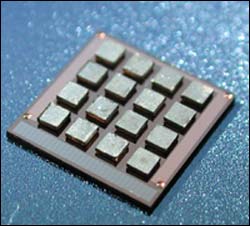

Silicon chip built by NIST researchers with 16 tiny gamma ray detectors that may help nuclear inspectors improve analysis of plutonium and other radioactive materials. Each detector is one millimeter square. Image credit: National Institute of Standards and Technology

Scientists at the Commerce Department’s National Institute of Standards and Technology (NIST) have designed and demonstrated the world’s most accurate gamma ray detector, which is expected to be useful eventually in verifying inventories of nuclear materials and detecting radioactive contamination in the environment.

The tiny prototype detector, described today at the American Physical Society national meeting in Baltimore, can pinpoint gamma ray emissions signatures of specific atoms with 10 times the precision of the best conventional sensors used to examine stockpiles of nuclear materials. The NIST tests, performed with different forms of plutonium at Los Alamos National Laboratory,* also show the prototype greatly clarifies the complex X-ray and gamma-ray emissions profile of plutonium.

Emissions from radioactive materials such as uranium or plutonium provide unique signatures that, if accurately measured, can indicate the age and enrichment of the material and sometimes its intended purpose or origin.

The 1-square-millimeter (mm) prototype collects only a small amount of radiation, but NIST and Los Alamos researchers are collaborating to make a 100-sensor array that could be deployed in the field, perhaps mounted on a cart or in a vehicle.

“The system isn’t planned as a primary detection tool,” says NIST physicist Joel Ullom. “Rather, it is intended for detailed analysis of material flagged by other detectors that have larger collection area but less measurement accuracy.” An array could be used by inspectors to determine, for example, whether plutonium is of a dangerous variety, whether nuclear fuel was made for energy reactors or weapons, or whether what appears to be radium found naturally in the environment is actually explosive uranium.

“People at Los Alamos are very excited about this work,” says Michael Rabin, a former NIST post-doc who now leads a collaborating team at Los Alamos. The Los Alamos National Laboratory operates and improves the capability to handle nuclear materials and sends scientists to participate in United Nations nuclear inspection teams.

An array of the new sensors might give inspectors new capabilities, such as enabling them to determine the plutonium content of spent reactor fuel without handling the fuel or receiving reliable information from the reactor’s operators. Plutonium content can indicate whether a reactor is being used to produce weapons or electrical power.

The gamma ray detector is a variation on superconducting “transition edge” sensor technology pioneered at NIST laboratories in Boulder, Colo., for analysis of X-rays (for astronomy and semiconductor analysis applications) and infrared light (for astronomy and quantum communications). The cryogenic sensors absorb individual photons (the smallest particles of light) and measure the energy based on the resulting rise in temperature. The temperature is measured with a bilayer of normal metal (copper) and superconducting metal (molybdenum) that changes its resistance to electricity in response to the heat from the radiation.

To stop gamma rays, which have higher energy than infrared light and X-rays, the sensors need to be topped with an absorbent material. A layer of tin, 0.25 mm thick, is glued on top of each sensor to stop the gamma rays. The radiation is converted to heat, or vibrations in the lattice of tin atoms, and the heat drains into the sensor, where the temperature change is measured. NIST researchers have developed microfabrication techniques to attach absorbers across an array.

Researchers expect the 100-detector array to measure 1 square centimeter in size. The NIST team has already developed multiplexed readout systems to measure the signals from large sensor arrays, and recent advances in commercial refrigeration technology are expected to allow pushbutton operation of the system without liquid cryogens.

Media Contact

More Information:

http://www.nist.govAll latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…