Scientists develop ’clever’ artificial hand

Scientists have developed a new ultra-light limb that can mimic the movement in a real hand better than any currently available. This research was presented today at the Institute of Physics conference Sensors and their Applications XIII which took place at the University of Greenwich, Kent, UK.

Every year 200 people in the UK lose their hands. Common causes include motorbike accidents and industrial incidents. Currently available prosthetic hands are either simple mimics that look like a hand but don’t move or moving hands which have a simple single-motor grip.

The human hand has 27 bones and can make a huge number of complex movements and actions. Dr Paul Chappell, a medical physicist from the University of Southampton has designed a prototype hand that uses 6 sets of motors and gears so that each of the five fingers can move independently. This enables it to make movements and grip objects in the same way a real human hand does.

The new hand, called the ’Southampton Remedi-Hand’, can be connected to muscles in the arm via a small processing unit and is controlled by small contractions of the muscles which move the wrist.

Dr Chappell said: “With this hand you can clutch objects such as a ball, you can move the thumb out to one side and grip objects with the index finger in the way you do when opening a lock with a key, and you can wrap your fingers around an object in what we call the power grip – like the one you use when you hold a hammer or a microphone.”

Dr Chappell and colleagues in the School of Electronics and Computer Science at the University of Southampton set out to try and build a hand which could mimic the movement and flexibility of the human hand and which was also very light. Heavy prosthetics can be extremely uncomfortable and cause injury to the area where it joins with the arm. The new hand they’ve developed is only 400g (even lighter that a real hand which weighs on average 500g).

They built the Remedi-Hand in three parts – the three middle fingers are very similar in size and movement so they made those identical. The pinky is a smaller version of the same. Each of these four fingers are made up of a motor attached to a gearbox attached to a carbon fibre finger. All of this is fitted to a carbon fibre palm. But the thumb was much more complicated and is the first artificially-made opposable thumb.

The human thumb can move in special ways the fingers can’t. It can rotate as well as flex and also move in a variety of different directions. It can also oppose (touch) each of the fingers in the hand to form a ’pinch’. To mimic this, the Remedi-Hand uses two motors – one to allow it to rotate and one to allow it to flex. “The real thumb can move in five types of way, we’ve managed to create a thumb that can mimic at least two of these which is a really exciting achievement. It’s a thumb that has really good flexibility and functionality” says Dr Chappell.

One of the key differences between mechanical, artificial, limbs is that they arn’t able to sense pressure or touch in the same way human limbs can. The next stage of Dr Chappell’s research is to integrate the latest sensors technology with the Remedi-Hand to create a ’clever’ hand which has better functionality and move like a real hand, but which can also sense how strongly it’s gripping an object or whether an object is slipping.

Dr Chappell and colleagues have already designed this ’clever’ hand and are about to start building a fully functioning prototype. It will have piezo-electric sensors in each of the five fingertips which will detect how much force is being exerted on the tip and translate this information into an electrical signal which will be fed to a small processor.

Dr Chappell said: “The aim is to create a hand with the sort of functionality a human hand has but also a sense of touch. This will let the hand know how tightly to grip an object like a coffee cup without dropping it, but not so tightly that it’s crushed. It’ll also have an integrated slip-sensor which will tell the hand if something is beginning to slip out of its grip so it can grip slightly harder. It’ll be quite a clever system.”

Media Contact

More Information:

http://www.iop.orgAll latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

A flexible and efficient DC power converter for sustainable-energy microgrids

A new DC-DC power converter is superior to previous designs and paves the way for more efficient, reliable and sustainable energy storage and conversion solutions. The Kobe University development can…

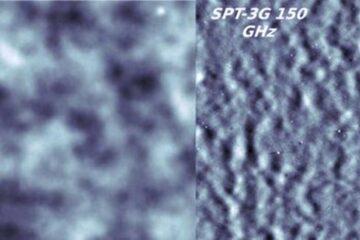

Technical Trials for Easing the (Cosmological) Tension

A new study sorts through models attempting to solve one of the major challenges of contemporary cosmic science, the measurement of its expansion. Thanks to the dizzying growth of cosmic…

Peptides on Interstellar Ice

A research team led by Dr Serge Krasnokutski from the Astrophysics Laboratory at the Max Planck Institute for Astronomy at the University of Jena had already demonstrated that simple peptides…