Finding the true measure of nanoscale ’roughness’

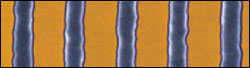

A colorized scanning electron microscope image shows the "waviness" or roughness of edges on reference lines made of silicon that are about 100 nanometers wide. Credit: B. Bunday, SEMATECH/K. Talbott, NIST

Straight edges, good. Wavy edges, bad. This simple description holds true whether you are painting the living room or manufacturing nanoscale circuit features.

In a technical paper* published in June, researchers at the National Institute of Standards and Technology (NIST) and SEMATECH describe an improved method for determining nanoscale “linewidth roughness,” an important quality control factor in semiconductor fabrication. Their research shows that current industry measurement methods may be exaggerating roughness of the smoothest circuit features by 40 percent or more above true values.

As circuit features shrink in size to below 50 nanometers, wavy or rough edges within semiconductor transistors may cause circuit current losses or may prevent the devices from reliably turning on and off with the same amount of voltage.

“With this type of measurement,” says NIST’s John Villarrubia, “besides the real roughness there is also a false roughness caused by measurement noise. Our method includes a correction to remove bias or systematic error from the measurement.”

Random noise, by definition, causes the measured value to be sometimes higher, sometimes lower than the true value, and can be minimized by simply averaging an adequate number of measurements. Systematic error, however, is consistently above or consistently below the true value due to some quirk of the measurement method.

The noise in nanoscale scanning electron microscope (SEM) images consistently adds extra roughness, says Villarrubia. The NIST/SEMATECH method involves taking two or more images at exactly the same location on a circuit feature, comparing the values, and subtracting the false roughness caused by measurement noise. SEM manufacturers should be able to incorporate the new method into their proprietary software for automated linewidth roughness measurements.

* J.S. Villarrubia and B.D. Bunday, Unbiased Estimation of Linewidth Roughness, Proceedings of SPIE 5752 (2005) pp. 480-488.

Media Contact

More Information:

http://www.nist.govAll latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…