Intermetallic Mystery Solved With Atomic Resolution Microscope

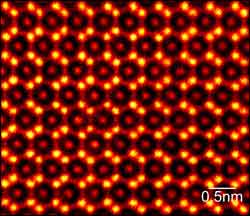

Atomic resolution Z-contrast image from the world’s most powerful microscope of a non-defective region of Cr2Hf. In this view, the hafnium atoms appear yellow and the chromium atoms are red. (Image: Sharvan Kumar)

Intermetallics could be the key to faster jets and more efficient car engines. But these heat-resistant, lightweight compounds have stumped scientists for decades. Why do so many break so easily? A team from Brown University, Oak Ridge National Laboratory, and UES Inc. used the world’s most powerful electron microscope to see, for the first time, atomic details that may provide the answer for the most common class of intermetallics. Their results – which could open the door for new materials for commercial use – are published in the current issue of Science.

Intermetallics can withstand searing heat and are often lightweight. These properties intrigue the aerospace, defense, energy and automotive industries, which are experimenting with this class of materials in hopes of building high-performance jet engines, improved rocket motors and missile components, more efficient steam turbines and better car engine valves.

Many intermetallics, however, break easily. These compounds are typically stronger than simple metals at high temperatures. Yet they are almost as fragile as ceramics at room temperature. This fragility limits their commercial use.

But why do most intermetallics shatter? How can that be prevented?

In a new report in Science, researchers from Brown University, Oak Ridge National Laboratory and UES Inc. for the first time describe detailed atomic arrangements in Laves phases – the most common class of intermetallics. Their discovery may be the first step in explaining the origin of this brittleness in some of these compounds.

“It has long been known that a dislocation, or crystal defect, moves when force is applied to a material. The easier it is to move this defect, the less brittle the material will be,” said Sharvan Kumar, professor of engineering at Brown University, who has studied Laves phases for more than a decade. “In materials with complex crystal structures, such as Laves phases, the atomic arrangement around these defects, and how these defects move, are not well understood.”

In the 1950s, a concept called “synchroshear” was proposed to explain how this defect moved in many complex structures. Under that theory, this movement is accomplished by coordinated shifting of atoms in two adjacent atomic layers. This synchronized movement is necessary to prevent atoms in one layer from colliding with atoms in the neighboring layer.

But because atoms are so tightly packed in compounds with complex structures, as they are in Laves phases, the theory could never be proven. There wasn’t a microscope powerful enough to show, in clear detail, how the atoms behaved.

Enter Matthew Chisholm, a staff researcher at Oak Ridge National Laboratory. Chisholm uses a unique Z-contrast scanning transmission electron microscope (STEM) to study defects in materials. The microscope was recently outfitted with an aberration-correction system, which corrects errors produced by imperfections in the electron lens. The system doubled the microscope’s resolving ability, making it the most powerful electron microscope on the planet.

Even though atoms in the test material – the Laves phase Cr2Hf – were spaced less than one ten-billionth of a meter away, the microscope produced crisp images of atoms arranged in tidy columns. Scientists put sheared material in the microscope, saw the defects and analyzed them.

“Aberration-correction combined with direct Z-contrast imaging produces an ideal technique to study unknown defect structures,” Chisholm said. “The resulting images have clearly shown for the first time that the accepted dislocation models built up over years of research on simple metals do not work in this more complex material.”

Kumar, who coordinated the project, said careful examination confirmed that synchroshear did indeed occur. “This is a first in science,” he said.

In the case of Laves phases, it is important to understand defect structures. With this knowledge, materials scientists may be able to identify methods that enhance their motion – and create intermetallic compounds that resist shattering.

The study illustrates the utility of Oak Ridge’s STEM in studying a variety of crystal structures and defects. The findings could be applied to materials with other complex structures, such as other classes of intermetallics as well as ceramics, inorganic salts and others.

The late Peter Hazzledine of UES Inc., a materials science research and development firm based in Dayton, Ohio, helped analyze and interpret the experimental results. Hazzledine was a leading authority on dislocation theory.

The U.S. Department of Energy’s Office of Basic Energy Sciences, the National Science Foundation-sponsored Materials Research Science and Engineering Center at Brown University, and the U.S Air Force Research Laboratory funded the work.

Media Contact

More Information:

http://www.brown.eduAll latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…