Materials On The Nanoscale May Sometimes Be Subject To The Same Physical Rules As Their Macro-World Counterparts

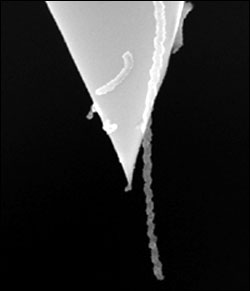

A nanospring hangs from the tip of an atomic force microscope. The spring measures 20 nanometers wide and about 1 micrometer in length.

Researchers at the Georgia Institute of Technology and NASA suggest that materials on the nanoscale may sometimes be subject to the same physical rules as their macro-world counterparts. The findings provide an exception to the conventional scientific notion that objects small enough to be measured in nanometers (one-billionth of a meter) behave according to different rules than larger objects.

A team led by Lawrence Bottomley in Georgia Tech’s School of Chemistry and Biochemistry and Jonathon Colton in the School of Mechanical Engineering found that the mechanical response of a multi-walled carbon nanospring was remarkably similar to the rules that govern the mechanical properties of springs on the macro scale. The results are published in the American Chemical Society journal Nano Letters, Volume 4, Number 6.

“Small may not necessarily be different when it comes to the mechanical properties of springs,” said Bottomley. The findings suggest there may be other nano materials that behave in ways similar to their macroscale counterparts.

The results were surprising because they ran counter to the common wisdom in the literature said Colton.

“You’ve got to study each case carefully, don’t just assume it’s different,” Bottomley added.

The team used an atomic force microscope to compress a multi-walled carbon nanospring attached to the cantilever probe tip. By simultaneously monitoring cantilever deflection, oscillation amplitude and resonance of the cantilever, the group found the nanospring compressed and buckled in the same ways a macroscale spring would.

In this one application we modeled the performance of a nanospring using the equations that are used to describe two macroscale springs in series. The agreement of data with the theory is remarkably good, said Bottomley.

In the future, the team plans further tests on multiwalled carbon nanosprings to correlate the number of walls, number of coils, and helical pitch with mechanical performance.

Other members of the research team included Mark Poggi, Jeffrey Boyles and Andrew McFarland from Georgia Tech; Cattien Nguyen from the ELORET Corporation and Ramsey Stevens and Peter Lillehei from NASA.

Media Contact

More Information:

http://www.gatech.eduAll latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

Combatting disruptive ‘noise’ in quantum communication

In a significant milestone for quantum communication technology, an experiment has demonstrated how networks can be leveraged to combat disruptive ‘noise’ in quantum communications. The international effort led by researchers…

Stretchable quantum dot display

Intrinsically stretchable quantum dot-based light-emitting diodes achieved record-breaking performance. A team of South Korean scientists led by Professor KIM Dae-Hyeong of the Center for Nanoparticle Research within the Institute for…

Internet can achieve quantum speed with light saved as sound

Researchers at the University of Copenhagen’s Niels Bohr Institute have developed a new way to create quantum memory: A small drum can store data sent with light in its sonic…