Germanium made compatible

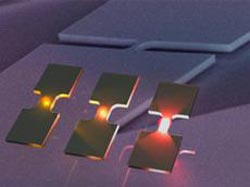

Light emitting bridges of germanium can be used for communication between microprocessors. (Graphic: Hans Sigg, PSI)<br>

Researchers from ETH Zurich, the Paul Scherrer Institute (PSI) and the Politecnico di Milano have jointly developed a manufacturing technique to render the semiconductor germanium laser-compatible through high tensile strain. In their paper recently published in Nature Photonics, they reveal how they can generate the necessary tensile strain efficiently.

The scientists demonstrate that they can use their method to effectively alter the optical properties of germanium, which is unsuitable for lasers as such: “With a strain of three per cent, the material emits around twenty-five times more photons than in a relaxed state,” explains Martin Süess, a doctoral student at the Laboratory for Nanometallurgy headed by Ralph Spolenak and the EMEZ at ETH Zurich. “That’s enough to build lasers with,” adds his colleague Richard Geiger, a doctoral student at the Laboratory for Micro- and Nanotechnology at the PSI and the Institute for Quantum Electronics at ETH Zurich under Jérôme Faist.

High tension through microbridges

In order to bring the germanium into a laser-compatible, stretched form with the new method, the researchers use the slight tension generated in germanium when it evaporates on silicon, strengthening this prestrain with so-called microbridges: they score exposed germanium strips, which remain attached to the silicon layer at both ends, in the middle on both sides. The two halves of the strip thus remain connected solely by an extremely narrow bridge, which is precisely where, for physical reasons, the strain of the germanium grows so intense that it becomes laser-compatible.

“The tensile strain exerted on the germanium is comparable to the force exerted on a pencil as two lorries pull upon it in opposite directions,” says Hans Sigg, the project manager at the PSI, explaining the feat on a micrometre scale in everyday proportions. The material properties change because the individual atoms move apart a little through the expansion of the material, which enables the electrons to reach energy levels that are favourable for the generation of light particles, so-called photons.

Germanium laser for the computer of the future

The interdisciplinary research team’s method could increase the performance of future computer generations considerably. After all, in order to improve computer performance, computer chips have constantly been made smaller and more densely packed. However, this approach will eventually hit a brick wall in the foreseeable future. “In order to increase performance and speed further, the individual components need to be linked more closely and communicate with each other more efficiently,” explains Süess. This requires new transmission paths that are faster than today, where the signals are still transmitted via electricity and copper cables.

“The way to go in future is light,” says Geiger. In order to be able to use this to transfer data, however, first of all light sources are needed that are so small as to fit onto a chip and react well to silicon, the base material of all computer chips. Silicon itself is not suitable for the construction of laser light, which is also the reason why it is so important for the researchers to make germanium laser-compatible: “Germanium is perfectly compatible with silicon and already used in the computer industry in the production of silicon chips,” explains Geiger. If it is possible to build tiny lasers out of germanium using the new method, a system change is within reach. “We’re on the right track,” says Süess. The international team of researchers is currently in the process of actually constructing a germanium laser with the new method.

Further reading

Süess MJ, Geiger R, Minamisawa RA, Schiefler G, Frigerio J, Chrastina D, Isella G, Spolenak R, Faist J & Sigg H: Analysis of enhanced light emission from highly strained germanium microbridges. Nature Photonics. 2013. Published online: 14 April 2013 doi:10.1038/nphoton.2013.67.

Media Contact

More Information:

http://www.ethz.chAll latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…