Brilliant light source for X-ray microscopy permits three-dimensional imaging of biological cells

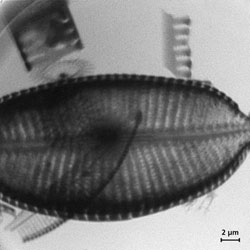

Image of a diatom (silica algae) taken using the X-ray microscope developed by the Fraunhofer Institute for Laser Technology ILT, Aachen, Germany<br>

The task of analyzing the internal structure of biological cells is a relatively complex affair. When using an electron microscope, the whole cells first have to be fixed, followed by the time-consuming task of preparing the individual slices. The surface of the slices can then be analyzed at high resolution, one slice at a time.

The procedure is much less laborious when using an X-ray microscope. Immediately after cryo-fixing of the whole cells, it is possible to obtain 3-dimensional images with a resolution of 20 nanometers (at current standards). The technique is rather similar to that of medical tomography (CAT scanning). X-ray microscopes can also be used in semiconductor electronics to examine current-carrying circuits at high resolution. This allows defects to be detected and visualized in working electronic devices.

To achieve the comparatively high resolution of 20 nanometers that distinguishes X-ray microscopy from basic light microscopy, a short-wavelength source in the soft X-ray range is required. Furthermore, the appropriate short exposure times call for the presence of a high photon flux. To date, the usual way of generating the necessary photon flow has involved the use of an electron storage ring. Such facilities are only available in a limited number of major research centers, and can only be used on-site, which makes it difficult for many users to take advantage of them.

The Fraunhofer Institute for Laser Technology has now developed a compact, integrated light source/collector lens system that enables powerful X-ray microscopes to be built on a laboratory scale. The volume of the resulting X-ray microscope does not exceed 2 m3. This permits it to be installed wherever it is needed.

The new X-ray microscope is capable of operating with exposure times in the single-digit second range for thin samples of less than 1 micrometer, or several tens of seconds for larger biological samples with a thickness of a few micrometers. Dr. Klaus Bergmann, who leads the Fraunhofer ILT project team, is certain that, “we will be able to bring the exposure time down to below 10 seconds for the larger samples too, by optimizing the design of the condenser mirror.”

A hollow-cathode-triggered pinch plasma is employed as the light source. The nitrogen working gas is repeatedly ionized in a pulsed high-current discharge, and briefly heated to a temperature of several hundred thousand degrees Celsius. Part of the coupled energy is emitted in the form of characteristic X-rays at a wavelength of 2.88 nanometers. The source can produce 4 x 10exp13 photons/(sr x pulse) at the 1s2-1s2p transitions of helium-like nitrogen. Using a suitably adapted collector optic and a pulse repetition rate of 1000 Hz, a photon flux of 1 x 10exp7 photons/(µmexp2 x s) can be generated on the sample. At this density, microscopic images of thick aqueous samples can be obtained with an exposure time of approximately ten seconds.

A first demonstrator model of the microscope has been built in collaboration with the Institute for X-Ray-Optics at the University of Applied Sciences in Koblenz and the company ACCEL Instruments GmbH in Bergisch-Gladbach, as part of a BMBF-funded collaborative research project. Next year's objective is to produce a light source for a commercial X-ray microscope suitable for tomography applications by integrating an appropriately adapted collector optic and further improving the brilliance.

CONTACTS at the Fraunhofer ILT:

If you have any questions about the X-ray microscope, please contact our experts:

Dr. rer. nat. Klaus Bergmann

Plasma technology department

Fraunhofer Institute for Laser Technology ILT

Phone +49 (0)241/8906-302

Fax +49 (0)241/8906-121

klaus.bergmann@ilt.fraunhofer.de

Dr. Willi Neff

Head of the plasma technology department

Fraunhofer Institute for Laser Technology ILT

Phone +49 (0)241/8906-142

Fax +49 (0)241/8906-121

willi.neff@ilt.fraunhofer.de

If you have questions concerning other subjects and wish to be put in touch with the relevant expert, please contact:

Dipl.-Phys. Axel Bauer

Head of Marketing and Communications

Fraunhofer Institute for Laser Technology ILT

Phone +49 (0)241/8906-194

Fax +49 (0)241/8906-121

axel.bauer@ilt.fraunhofer.de

Media Contact

More Information:

http://www.ilt.fraunhofer.de/eng/100031.htmlAll latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…