Intelligent transit box for vaccinations

Vaccination supplies can be rendered useless if their temperature rises above the permitted maximum. MEDICASE has developed an intelligent transit box which ensures tight temperature control and which has a built-in data logger to provide a temperature audit trail.

Research shows that a surprising proportion of medical supplies and samples become damaged during transit. This represents a serious problem both for supplier and end users. A customer recently received a consignment of vaccinations worth millions of euros, which turned out to be denatured. The damage arose because the plane carrying the consignment had had to wait a long time on the runway, and this had caused an unacceptable rise in temperature.

“It doesn’t take long for a vaccine to become useless if the ambient temperature rises to 20-25° Celsius,” explains Colin Rickson of Kryotrans, and head of MEDICASE exploitation. “The conventional solution is to use packaging made from expanded polystyrene and cardboard, but these can only maintain the temperature for a limited period and are difficult to dispose of.”

Part of the problem with conventional packaging is that the end user can’t be certain that the temperature limits have been exceeded. “When meningitis vaccinations were given to high-risk groups in Wales several years ago, it was subsequently found that over half had not received protection. The cause was traced to overheating of the vaccines in transit,” adds Rickson.

The MEDICASE reusable transit box maintains temperature for up to seven days, and has a built-in data logger that records both inside and ambient temperature. Also, because the boxes are reusable, the thermal insulation characteristics can be improved without the environmental impact that disposable boxes carry. “We’ve also developed a version that can tell you what country it’s in and what the temperature is,” says Rickson. “It has, in addition to the data logger, a built-in GPS satellite navigation receiver and GSM mobile phone for communications.”

“We anticipate that the consortium will start production of the units will early in 2005,” says Rickson. “We shall be exhibiting fully operational pre-production prototypes at the IST 2004 event at The Hague [15-17 November 2004].”

Media Contact

More Information:

http://istresults.cordis.lu/All latest news from the category: Health and Medicine

This subject area encompasses research and studies in the field of human medicine.

Among the wide-ranging list of topics covered here are anesthesiology, anatomy, surgery, human genetics, hygiene and environmental medicine, internal medicine, neurology, pharmacology, physiology, urology and dental medicine.

Newest articles

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…

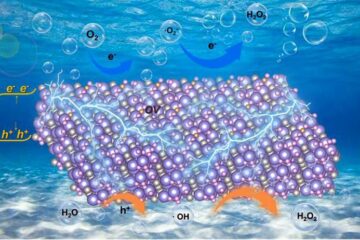

Oxygen vacancies mediated ultrathin Bi4O5Br2 nanosheets

… as efficient piezocatalyst for synthesis of H2O2 from pure water. As an important chemical raw material, hydrogen peroxide (H2O2) is widely applied in various aspects of industry and life….