New version of syngo.via brings "anatomical intelligence" to diagnostic reading

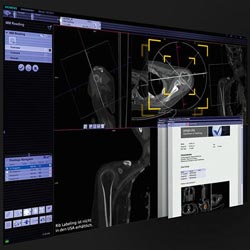

syngo.via General Engine is a new package of highly automated and standardized applications. As depicted here, the feature "Anatomical Range Presets" displays a quick, precise, optimal view of selected anatomical regions. The syngo.via Advanced Reporting tool, part of the syngo.via General Engine, helps radiologists create clear, well-structured reports for the referring or follow-up physicians.<br>

Siemens Healthcare introduces version VA30 of its routine 3D and advanced reading software syngo.via, featuring new applications and functionalities that further streamline and accelerate the syngo.via experience.

The latest innovation is the syngo.via General Engine, a new package of highly automated and standardized applications. “Anatomical Range Presets,” for example, identifies individual regions of the body on images captured using computed tomography (CT) and magnetic resonance imaging (MRI), aligns the image projections accordingly, then selects detailed views to facilitate case preparation. For customers, this means greater efficiency and enables higher diagnostic confidence.

Siemens is making syngo.via more anatomically intelligent to support radiologists and medical technology personnel in their routine workflows. The software “understands” human anatomy and prepares the images for diagnostic reading. Syngo.via VA30 features “Automatic Rib Labeling,” for example, which automatically identifies and labels the ribs in CT scans. Until now, radiologists had to identify the ribs manually. Given the unique shape of the ribs, this can be time-consuming and lead to errors, especially in complex diagnostic environments such as oncology.

Anatomical intelligence is also a hallmark of the new syngo.via General Engine software package with which customers can upgrade their software. The package includes the “Anatomical Range Presets” feature, which displays a quick, precise, optimal view of selected anatomical regions. To facilitate diagnoses, users often create such views manually, performing the multi-step process of selecting the relevant area, aligning the image projections accordingly, and editing the detailed view. This takes time, requires anatomical expertise, and is error-prone. The new application from Siemens largely automates these steps. This delivers a consistent quality of the resulting anatomical views and snapshots that does not depend on the skill of the specific user. Using a technology akin to facial recognition in digital photography, syngo.via is able to recognize shoulders, spines, hips, etc. in clinical images and optimize how they are displayed in their anatomical environment. The presets are initially available for specific anatomical regions in CT and MRI images.

Following an examination, the radiological diagnostic report plays a key role in the treatment of the patient. The syngo.via Advanced Reporting tool, part of the syngo.via General Engine, helps radiologists create clear, well-structured reports for the referring or follow-up physicians. Standardized templates make it easier to create reports but can still be customized to individual needs, and findings from multiple examinations can be consolidated into a single report. In the past, multiple diagnoses meant having different documents pertaining to a single case. Now, the diagnostic report reflects the patient's entire disease profile. This makes it much easier for doctors to form a comprehensive assessment of the patient's condition, which helps to improve the quality of treatment.

The Siemens Healthcare Sector is one of the world's largest suppliers to the healthcare industry and a trendsetter in medical imaging, laboratory diagnostics, medical information technology and hearing aids. Siemens offers its customers products and solutions for the entire range of patient care from a single source – from prevention and early detection to diagnosis, and on to treatment and aftercare. By optimizing clinical workflows for the most common diseases, Siemens also makes healthcare faster, better and more cost-effective. Siemens Healthcare employs some 52,000 employees worldwide and operates around the world. In fiscal year 2013 (to September 30), the Sector posted revenue of 13.6 billion euros and profit of 2.0 billion euros. For further information please visit: http://www.siemens.com/healthcare

Syngo.via can be used as a standalone device or together with a variety of syngo.via-based software options, which are medical devices in their own rights.

Syngo.via and the syngo.via-based software options are pending in some countries the necessary clearances and thus are not available for sales in all countries.

The syngo.via General Engine is part of the medical device syngo.via.

Rib Labeling is not available in the US.

Reference Number: HIM201311012e

Contact

Ms. Stefanie Schiller

Healthcare Sector

Siemens AG

Henkestr. 127

91052 Erlangen

Germany

Tel: +49 (9131) 84-7803

schiller.stefanie@siemens.com

Media Contact

All latest news from the category: Medical Engineering

The development of medical equipment, products and technical procedures is characterized by high research and development costs in a variety of fields related to the study of human medicine.

innovations-report provides informative and stimulating reports and articles on topics ranging from imaging processes, cell and tissue techniques, optical techniques, implants, orthopedic aids, clinical and medical office equipment, dialysis systems and x-ray/radiation monitoring devices to endoscopy, ultrasound, surgical techniques, and dental materials.

Newest articles

Bringing bio-inspired robots to life

Nebraska researcher Eric Markvicka gets NSF CAREER Award to pursue manufacture of novel materials for soft robotics and stretchable electronics. Engineers are increasingly eager to develop robots that mimic the…

Bella moths use poison to attract mates

Scientists are closer to finding out how. Pyrrolizidine alkaloids are as bitter and toxic as they are hard to pronounce. They’re produced by several different types of plants and are…

AI tool creates ‘synthetic’ images of cells

…for enhanced microscopy analysis. Observing individual cells through microscopes can reveal a range of important cell biological phenomena that frequently play a role in human diseases, but the process of…