Medical sensors improve with holey gold nanostructures

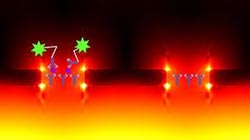

Localized surface plasmon resonance (bright areas) around a gold nanohole enhances the fluorescence of a biomarker dye (Y-shaped molecule) when a specific molecule of interest (purple circle) is present. <br>Copyright : © 2013 A*STAR Institute of High Performance Computing <br>

Recent advances in nanotechnology are providing new possibilities for medical imaging and sensing. Gold nanostructures, for example, can enhance the fluorescence of marker dyes that are commonly used to detect biomolecules and diagnose specific diseases.

Now, Ping Bai at the A*STAR Institute of High Performance Computing, Singapore, and co-workers have developed a fast and inexpensive way to fabricate arrays of gold nanoholes. The researchers have shown that sensor chips built using these nanostructures can accurately detect cancer-related molecules in blood and are small enough to be used in portable medical devices.

Nanohole arrays are designed so that incident light of certain wavelengths will induce large-scale oscillations of the gold electrons, known as localized surface plasmon resonance (SPR). The localized SPR focuses the absorbed light energy to enhance fluorescence (see image).

“Commercial SPR systems are already used in hospital laboratories, but they are bulky and expensive,” says Bai. “We would like to develop small, handheld devices for on-the-spot clinical use. This requires localized SPR, for which we need nanohole arrays.”

Previously, nanohole arrays have been created using electron-beam lithography (EBL), which is expensive and time consuming. Bai and co-workers used EBL to create a nickel mold and then used the mold to print nanohole patterns onto a photoresist material. The researchers made the nanostructures by evaporating gold onto the patterned structure before peeling off the photoresist material. Because the nickel mold can be reused many times, this method — called nano-imprinting — can produce large numbers of gold nanohole arrays.

“We fabricated arrays of 140 nanometer-square nanoholes with very few defects,” says Bai. As a first demonstration, the researchers showed that a sensor chip made with their nanohole arrays could detect prostate cancer antigens in blood, and was ten times more sensitive than an identical device that used a gold film without nanoholes. Optimizing the chip design would further improve the sensitivity, Bai notes.

The team believes that these chips could be incorporated into cheap and portable point-of-care devices for rapid diagnosis of diseases such as dengue fever. “The microfluidic cartridge built using our nanohole arrays is about the size of a credit card,” says Bai. “In the future, we hope to build detectors that use very simple light sources, such as LEDs, and simple detectors similar to smartphone cameras. These devices will have widespread applications across medical science and could even be used to detect contaminants in food, water or the air.”

The A*STAR-affiliated researchers contributing to this research are from the Institute of High Performance Computing, Institute of Materials Research and Engineering and Singapore Institute of Manufacturing Technology

Associated links

Wong, T. I., Han, S., Wu, L., Wang, Y., Deng, J. et al. High throughput and high yield nanofabrication of precisely designed gold nanohole arrays for fluorescence enhanced detection of biomarkers. Lab on a Chip 13, 2405–2413 (2013).

http://www.sciencedirect.com/science/article/pii/S0261306913005074

Media Contact

More Information:

http://www.a-star.edu.sgAll latest news from the category: Medical Engineering

The development of medical equipment, products and technical procedures is characterized by high research and development costs in a variety of fields related to the study of human medicine.

innovations-report provides informative and stimulating reports and articles on topics ranging from imaging processes, cell and tissue techniques, optical techniques, implants, orthopedic aids, clinical and medical office equipment, dialysis systems and x-ray/radiation monitoring devices to endoscopy, ultrasound, surgical techniques, and dental materials.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…