Ground breaking hip and stem cell surgery in Southampton

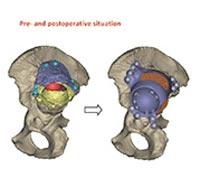

The purple area is the 3D printed implant and the oragne is the stem cell graft

The 3D printed hip, made from titanium, was designed using the patient’s CT scan and CAD CAM (computer aided design and computer aided manufacturing) technology, meaning it was designed to the patient’s exact specifications and measurements.

The implant will provide a new socket for the ball of the femur bone to enter. Behind the implant and between the pelvis, doctors have inserted a graft containing bone stem cells.

The graft acts as a filler for the loss of bone. The patient’s own bone marrow cells have been added to the graft to provide a source of bone stem cells to encourage bone regeneration behind and around the implant.

Southampton doctors believe this is a game changer. Douglas Dunlop, Consultant Orthopaedic Surgeon, conducted the operation at Southampton General Hospital. He says: “The benefits to the patient through this pioneering procedure are numerous. The titanium used to make the hip is more durable and has been printed to match the patient’s exact measurements – this should improve fit and could recue the risk of having to have another surgery.

“The bone graft material that has been used has excellent biocompatibility and strength and will fill the defect behind the bone well, fusing it all together.”

Over the past decade Mr Dunlop and Professor Richard Oreffo, at the University of Southampton, have developed a translational research programme to drive bone formation using patient skeletal stem cells in orthopaedics.

The graft used in this operation is made up of a bone scaffold that allows blood to flow through it. Stem cells from the bone marrow will attach to the material and grow new bone. This will support the 3D printed hip implant.

Professor Oreffo comments: “The 3D printing of the implant in titanium, from CT scans of the patient and stem cell graft is cutting edge and offers the possibility of improved outcomes for patients.

“Fractures and bone loss due to trauma or disease are a significant clinical and socioeconomic problem. Growing bone at the point of injury alongside a hip implant that has been designed to the exact fit of the patient is exciting and offers real opportunities for improved recovery and quality of life.”

For the patient, Meryl Richards, from Hampshire, the procedure means an end to her hip troubles. In 1977 she was involved in a traffic accident and since then has had to have six operations to mend her hip.

She says: “The way medicine has evolved is fantastic. I hope that this will be the last time that I have to have a hip operation. I feel excited to have this pioneering surgery and I can see what a benefit it will have to me.”

Media Contact

More Information:

http://www.southampton.ac.uk/mediacentre/news/2014/may/14_88.shtmlAll latest news from the category: Medical Engineering

The development of medical equipment, products and technical procedures is characterized by high research and development costs in a variety of fields related to the study of human medicine.

innovations-report provides informative and stimulating reports and articles on topics ranging from imaging processes, cell and tissue techniques, optical techniques, implants, orthopedic aids, clinical and medical office equipment, dialysis systems and x-ray/radiation monitoring devices to endoscopy, ultrasound, surgical techniques, and dental materials.

Newest articles

Peptides on Interstellar Ice

A research team led by Dr Serge Krasnokutski from the Astrophysics Laboratory at the Max Planck Institute for Astronomy at the University of Jena had already demonstrated that simple peptides…

A new look at the consequences of light pollution

GAME 2024 begins its experiments in eight countries. Can artificial light at night harm marine algae and impair their important functions for coastal ecosystems? This year’s project of the training…

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…