Engineers complete first comprehensive mesh-free numerical simulation of skeletal muscle tissue

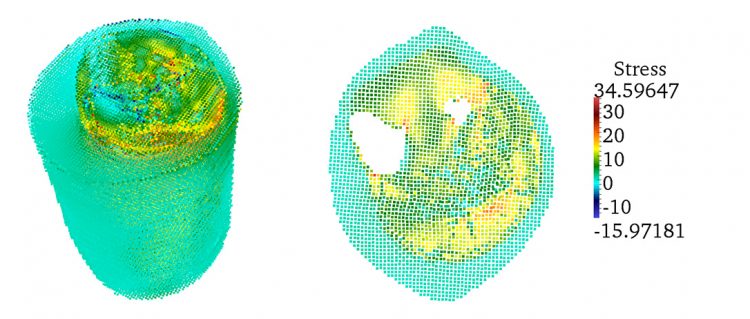

From left: Distribution of maximum stress in the 3D model; and a cross-section showing maximum stress.

Engineers at the University of California, San Diego, have completed the first comprehensive numerical simulation of skeletal muscle tissue using a method that uses the pixels in an image as data points for the computer simulation—a method known as mesh-free simulation.

The researchers, led by J.S. Chen, the William Prager Professor of structural engineering at the Jacobs School of Engineering at UC San Diego, presented their findings on the development of this method at the CompIMAGE'14 conference in Pittsburgh this month. Chen also gave a keynote speech about the work.

Chen’s group has now expanded the use of mesh-free simulation methods to investigate aging and disorders impacting muscle functions, such as muscular dystrophy. “Another area of application for this framework would be the simulation of tissue injuries caused by extreme events such as blasts, car crashes and sport collisions”. Chen said. This will require adding the mechanics of tissue damage to the simulation model, including how tissue behaves and functions under high velocity impact.

Traditionally, engineers rely on the reconstruction of the geometry captured by from CT scans or MRI images to create simulation models of biological materials, such as muscle tissue. The reconstructed 3D geometry is then used to generate a mesh to describe the material’s structure—this is known as the conventional finite element method. This procedure is extremely time consuming and labor intensive.

Using the mesh-free method cuts back on the amount of time for the process of generating the simulation model because researchers don’t have to build a mesh for the structure they’re trying to simulate, said Ramya Rao Basava, the lead Ph.D. student on the study.

For this study, researchers in Chen’s group used Magnetic Resonance and Diffusion Tensor images for the mesh-free simulation. The images were obtained through the Department of Radiology at UC San Diego. The image data acquired was from 10 volunteers between the ages of 20 to 90. The younger subjects were mostly in their 20s and 30s, the older ones mostly in their 80s.

Chen’s research group used the simulation techniques they developed to look at how much force is generated from various muscle systems, and more specifically at how loss of force relates to loss of muscle volume due to aging. They found that the loss of force is greater than the loss of volume, which is consistent with prior physiological studies.

Chen is a leader in the field of computational mechanics, particularly mesh-free methods for structures and materials subjected to large deformation and damages.

Chen’s research group has advanced mesh-free method research to achieve high accuracy and efficiency in simulating a wide range of engineering and scientific problems that are difficult or impossible to simulate via mesh-based methods, for example, fragment-impact modeling for homeland security applications, landslide simulations in natural disaster predictions, manufacturing processes and contact-impact modeling in the automotive industry, multi-scale materials modeling in material science applications and modeling of DNA-protein interaction, among others. Recently, his research group has started venturing into the field of simulation for biological materials such as muscle tissue.

Chen is also the faculty director of UC San Diego’s new Center for Extreme Events Research, which has been established to offer solutions to a wide range of challenges associated with extreme events, such as blasts and landslides, and brings together unique experimental technologies and advances in computational methods.

Ioana Patringenaru

Jacobs School of Engineering

Phone: 858-822-0899

ipatrin@ucsd.edu

Media Contact

More Information:

http://www.jacobsschool.ucsd.edu/news/news_releases/release.sfe?id=1577All latest news from the category: Medical Engineering

The development of medical equipment, products and technical procedures is characterized by high research and development costs in a variety of fields related to the study of human medicine.

innovations-report provides informative and stimulating reports and articles on topics ranging from imaging processes, cell and tissue techniques, optical techniques, implants, orthopedic aids, clinical and medical office equipment, dialysis systems and x-ray/radiation monitoring devices to endoscopy, ultrasound, surgical techniques, and dental materials.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…