How new substances form

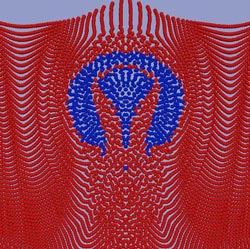

Simulations reveal how chemical compounds are formed. Image source: SFB 716<br>

Inside of a bubble column, gas bubbles rise in a liquid. While this happens, chemical processes take place at their outer layers where different substances are in contact. About 90 percent of all products of the chemical industry are generated in this way. These products are ultimately incorporated into a variety of goods such as cosmetics, clothing, plastic items (bottles, garbage bags, foils), as well as synthetic fuels, such as those used for the propulsion of ships or missiles.

Simulations are one way to better understand and optimize the process of formation of those chemical products. So far, scientists mostly modeled the circulation of gas bubbles and the induced fluid flow, using computer simulations. However, this approach only allows for limited predictions about varying process conditions.

This could be changed by particle simulations, which were developed at the Collaborative Research Center (SFB 716) focusing on “Dynamic Simulations of Systems with Large Numbers of Particles” at the University of Stuttgart. The research team led by Prof. Dr.-Ing. Ulrich Nieken at the Institute of Chemical Engineering concentrates its research efforts on the boundary layers of the gas bubbles, since this is where the actual chemical reactions take place.

The researchers develop computer simulations to test relevant factors such as column size, quantities of liquid, or different combinations of substances. By means of these simulations, they want to clarify important details like: Under what conditions do the desired reactions occur? What chemical phenomena play a role? What quantity of the final product can be produced, and how can these processes be accelerated to optimize throughput?

To achieve this, the researchers develop complex numerical calculation schemes for which they utilize high performance computer clusters or graphics cards. The methods developed by the scientists of the SFB are cutting edge in simulations of the described processes.

The current research results were published in July as part of a special issue of the journal “Chemie Ingenieur Technik” on bubble columns. “Chemie Ingenieur Technik” is the most important German-language magazine for process engineers, technical chemists, apparatus engineers, and biotechnologists.

Contact:

Prof. Dr.-Ing. Ulrich Nieken, University of Stuttgart, Institute of Chemical Process Engineering, phone: 0711/685-85230, E-Mail: ulrich.nieken(at)icvt.uni-stuttgart.de

Media Contact

More Information:

http://www.uni-stuttgart.deAll latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…