Stop and search

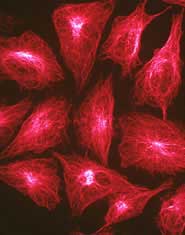

Proteins from the cell’s skeleton make roaming robots. <br>© SPL <br>

Glowing nanobots map microscopic surfaces.

Unleashing hordes of molecular robots to explore a surface’s terrain can produce maps of microscopic structures and devices with higher resolutions than those produced by conventional microscopes, new research shows.

Each robot has a ’light’ attached to it, allowing its random movements to be tracked around obstacles, through cracks or under overhangs. Adding the paths of hundreds of wandering nanobots together builds up a map of the entire surface1.

To build their nanobots, Viola Vogel and colleagues at the University of Washington in Seattle modified natural molecular machines called microtubules. These are cylinders of a protein called tubulin, stacked like the bricks in a chimney. Normally, they act as scaffolding inside cells, known as the cytoskeleton, which controls cell shape. ’Motor’ proteins called kinesins shuttle materials around cells along the microtubule gangways.

To create self-propelled nanoscale robots, Vogel’s team reversed nature’s arrangement. By fixing kinesin molecules all over a surface, wormlike microtubules propel themselves randomly all over the surface. By attaching a fluorescent dye to the microtubules, the researchers can follow where they go – and where they don’t.

The immobilized kinesin molecules drive microtubules up and down smooth slopes, but they cannot propel them up steep walls because the microtubules are too stiff to bend up a sharp incline. These limits to the tubule’s peregrinations produce a topographical map of surfaces.

Because microtubule nanobots can penetrate holes, cavities and pores, they can reach places that cannot be seen by passively gazing through a microscope. Their progress would still remain visible if the surface is transparent to the light emitted by the probes.

What’s more, Vogel’s team claims, the robots could be designed to investigate specific aspects of a surface, such as regions that are attractive or repulsive to water. This information could help researchers to understand, for example, the structure of porous materials, the architecture of biological tissues, or the shapes of large molecules sitting on a surface.

In principle, nanobots should be able to see features that are less than 50 nanometres (millionths of a millimetre) across. Smaller details – perhaps down to one nanometre – might be visible if smaller ’molecular robots’ are created, the researchers hope.

The time required for the robots to explore the accessible surface fully depends on how many of them there are and on how fast they move (about 250 nm per second for microtubules). The researchers were able to map out their test surface by superimposing 500 images at a rate of one every 5 seconds.

References

Hess, H., Clemmens, J., Howard, J. & Vogel, V. Surface imaging by self-propelled nanoscale probes. Nano Letters 2, 113 – 116, (2002).

Media Contact

All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…