Harvard scientists partner to develop and distribute new tuberculosis vaccine

Bioengineers and public health researchers at Harvard University have developed a novel spraying method for delivering the most common tuberculosis (TB) vaccine, providing a new low-cost and scaleable technique that offers needle-free delivery and greater stability at room temperature than existing methods. The process could one day provide a better approach for vaccination against TB and help prevent the related spread of HIV/AIDS in the developing world.

Researcher David Edwards will describe the finding — and ongoing work to encourage widespread use of the new vaccine in the developing world — this week at the annual meeting of the American Association for the Advancement of Science in San Francisco.

Edwards, an international leader in aerosol drug and vaccine delivery, sees great promise for the advance, which he and his colleagues hope to develop in the next few years through a partnership with the international not-for-profit Medicine in Need (MEND), based in Cambridge, Mass., Paris, and Cape Town.

His research, as well as the efforts to distribute the new vaccine in conjunction with MEND, are supported by a Grand Challenge Grant from the Bill and Melinda Gates Foundation.

“With the increasing incidence of tuberculosis and drug-resistant disease in developing countries due to HIV/AIDS, there is a need for vaccines that are more effective than the present Bacillus Calmette-Guérin (BCG) vaccine,” says Edwards, the Gordon McKay Professor of the Practice of Biomedical Engineering in Harvard's School of Engineering and Applied Sciences. “An optimal new vaccine would provide a safe and more consistent degree of protection by eliminating needle injection and refrigerated storage.”

BCG, the most widely administered childhood vaccine in the world with 100 million infant administrations annually, is presently dried by freezing and delivered by needle injection. The commercial formulation requires refrigerated storage and has shown variable degrees of protection against tuberculosis in different parts of the world. Because of such limitations, public health experts and physicians have long seen a need for alternatives to the traditional BCG vaccine and current treatment strategies.

The spray drying process Edwards developed for the BCG vaccine is similar to the way manufacturers prepare powdered milk. In fact, Edwards's first exposure to the spray drying process occurred when he was working with a spray dryer to produce highly respirable drug aerosols in a food science lab.

While spray drying of small and large molecules is common in the food, cosmetic, and pharmaceutical industries, the method has not been commonly used for drying cellular material. Most important, the new technique enables the BCG vaccine, and potentially other bacterial and viral-based vaccines, to be dried without the traditional problems associated with standard freezing.

“Unlike traditional freezing techniques, spray drying is lower-cost, easily scaleable for manufacturing, and ideal for use in needle-free formulations, such as inhalation,” Edwards says. “Its greater stability at room temperature and viability ultimately could provide a more practical approach for creating and delivering a vaccine throughout the world.”

Media Contact

More Information:

http://www.harvard.eduAll latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…

A flexible and efficient DC power converter for sustainable-energy microgrids

A new DC-DC power converter is superior to previous designs and paves the way for more efficient, reliable and sustainable energy storage and conversion solutions. The Kobe University development can…

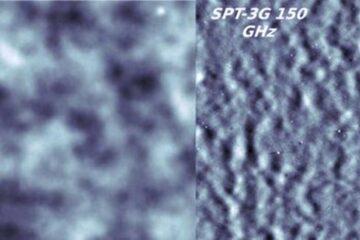

Technical Trials for Easing the (Cosmological) Tension

A new study sorts through models attempting to solve one of the major challenges of contemporary cosmic science, the measurement of its expansion. Thanks to the dizzying growth of cosmic…