Toxicology-on-a-Chip Tool Readies for Market

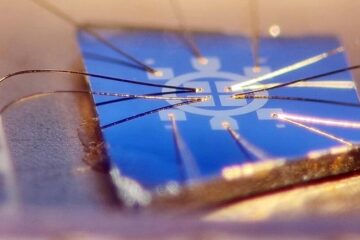

This slide includes approximately 2,000 combinations of eight enzymes used in human liver metabolism. To detect toxic drug compound reactions, the slide is “stamped” with a second slide of human organ cells. Photo by RPI/Moo-Yeal Lee and Jonathan Dordick

University and biotech company collaboration prepares MetaChip for technology transfer

Recalls of popular prescription drugs are raising public concern about the general safety of new pharmaceuticals. A collaborative group of researchers says that identifying which drug candidates are toxic early in the discovery process can help prevent harmful pharmaceuticals from being placed on the market in the first place, and they have developed a tool to do it.

Researchers at Rensselaer Polytechnic Institute, University of California-Berkeley, and Solidus Biosciences Inc. have developed a biochip, called the MetaChip, which can analyze drug candidates for toxicity and eliminate harmful ones before they advance to pre-clinical stages. Now beginning the second phase of funding for the National Institutes of Health (NIH)-supported project, researchers are working to optimize the technology for the end user: pharmaceutical and biotechnology companies. The researchers are working to bring the MetaChip to market within a year.

“Compounds can be screened early, quickly, and effectively by the MetaChip to prevent toxic drugs from getting through the discovery process, being put on the market, and then getting recalled, such as we’ve seen with several high-profile cases recently,” says Jonathan Dordick, the Howard P. Isermann ’42 Professor of Chemical and Biological Engineering at Rensselaer.

“Weeding out toxic compounds earlier would also allow pharmaceutical companies to evaluate more compounds and more efficiently identify those that are most likely to become successful drugs,” adds Douglas Clark of the Chemical Engineering Department at the University of California-Berkeley.

Dordick and Clark are also the co-founders of Solidus Biosciences, a biotech company located at the Rensselaer Incubator for start-up businesses.

The MetaChip (metabolizing enzyme toxicology assay chip) mimics the effects of metabolism in the human liver where enzymes break down, neutralize, and excrete chemicals from food and pharmaceuticals. In many cases, the metabolized chemicals, called metabolites, are harmless or even beneficial. But some metabolites are toxic, and this toxicity can be difficult to predict or find at early stages of drug discovery with current testing methods.

“The relatively slow pace of technology development in toxicology and clinical safety evaluation that could be used in early phases of drug development continues to hinder the progression of lead compounds to pharmaceuticals,” Dordick says. “In addition to safety concerns, drug discovery is an extremely costly process with more than $1 billion invested in each approved drug. For the first time, the MetaChip can enable the initial and high-throughput analysis of metabolism-induced toxicology to be performed before significant resources are invested in the drug’s development.”

Solidus Biosciences recently received a $1.7 million, three-year award from NIH through its Small Business Technology Transfer Program to optimize the MetaChip for market. Rensselaer will receive approximately $500,000 as a sub-contractor of the award. The technology has been patented by Rensselaer Polytechnic Institute and University of California-Berkeley and licensed exclusively to Solidus Biosciences.

The MetaChip uses a culturing method by combining enzyme catalysis with cell-based screening on a single microscale chip. The drug candidates are added to a chip containing approximately 2,000 combinations of eight enzymes used in human liver metabolism and then sandwiched with a slide of human organ cells in order to detect toxic reactions to the compound. When toxic reactions are detected, the toxic drug compounds are eliminated as potential candidates for further development as new pharmaceuticals. The researchers are also working to develop an automated MetaReader device to quickly analyze the results.

Dordick, Clark, and collaborators published findings on the MetaChip in the Jan. 25, 2005 issue of Proceedings of the National Academy of Sciences in a paper titled “Metabolizing Enzyme Toxicology Assay Chip (MetaChip) for High-Throughput Microscale Toxicity Analyses.” The peer-reviewed publication defines the technology and results of testing in more detail.;

Development of the MetaChip technology is part of several NIH-funded research projects at Rensselaer seeking more efficient ways to synthesize and identify compounds that merit further development as possible new drugs.

Biotechnology and Interdisciplinary Studies at Rensselaer

At Rensselaer, faculty and students in diverse academic and research disciplines are collaborating at the intersection of the life sciences and engineering to encourage discovery and innovation. Rensselaer’s four biotechnology research constellations – biocatalysis and metabolic engineering, functional tissue engineering and regenerative medicine, biocomputation and bioinformatics, and integrative systems biology — engage a multidisciplinary mix of faculty and students focused on the application of engineering and physical and information sciences to the life sciences. Ranked among the world’s most advanced research facilities, Rensselaer’s Center for Biotechnology and Interdisciplinary Studies provides a state-of-the-art platform for collaborative research and world-class programs and symposia.

About Rensselaer

Rensselaer Polytechnic Institute, founded in 1824, is the nation’s oldest technological university. The university offers bachelor’s, master’s, and doctoral degrees in engineering, the sciences, information technology, architecture, management, and the humanities and social sciences. Institute programs serve undergraduates, graduate students, and working professionals around the world. Rensselaer faculty are known for pre-eminence in research conducted in a wide range of fields, with particular emphasis in biotechnology, nanotechnology, information technology, and the media arts and technology. The Institute is well known for its success in the transfer of technology from the laboratory to the marketplace so that new discoveries and inventions benefit human life, protect the environment, and strengthen economic development.

Media Contact

More Information:

http://www.rpi.eduAll latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Next-generation treatments hitch a ride into cancer cells

Researchers from Osaka University discover that opening a channel into cancer cells helps antisense oligonucleotide drugs reach their targets. Antisense oligonucleotides (ASOs) are next-generation drugs that can treat disease by…

Boron deficiency: oilseed rape reacts as with infection and pest infestation

Genetic mechanisms uncovered… Boron deficiency has a devastating effect on oilseed rape and related plants. However, little is known about the underlying genetic mechanisms. A study shows that the response…

Quantum Precision: A New Kind of Resistor

Researchers at the University of Würzburg have developed a method that can improve the performance of quantum resistance standards. It´s based on a quantum phenomenon called Quantum Anomalous Hall effect….