Engineers create optoelectronic tweezers to round up cells, microparticles

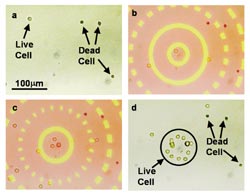

The images above show selective collection of live cells from a mixture of live and dead cells. In (a), the cells are randomly positioned. In (b) and (c), a series of optically projected concentric circles round up live cells, while dead cells (stained with Trypan blue dye) leak out through the dark gaps and are not collected. The optical pattern has a yellowish colour, while weak background scattered light results in a pinkish hue in the non-patterned areas. Section (d) shows the collection of live cells rounded up by the optoelectronic tweezer. (Courtesy of Wu Lab, UC Berkeley)

Rounding up wayward cells and particles on a microscope slide can be as difficult as corralling wild horses on the range, particularly if there’s a need to separate a single individual from the group.

But now, a new device developed by University of California, Berkeley, engineers, and dubbed an “optoelectronic tweezer,” will enable researchers to easily manipulate large numbers of single cells and particles using optical images projected onto a glass slide coated with photoconductive materials.

“This is the first time a single light-emitting diode has been used to trap more than 10,000 microparticles at the same time,” said Ming Wu, UC Berkeley professor of electrical engineering and computer sciences and principal investigator of the study. “Optoelectronic tweezers can produce instant microfluidic circuits without the need for sophisticated microfabrication techniques.”

This technique, reported in the July 21 issue of the journal Nature, has an advantage over existing methods of manipulating cells, such as optical tweezers that use focused laser beams to “trap” small molecules. Such techniques require high-powered lasers, and their tight focusing requirements fundamentally limit the number of cells that can be moved at the same time.

Wu and his UC Berkeley graduate students, Pei Yu Chiou and Aaron Ohta, also improved upon other cell manipulation tools that use electrokinetic forces to create electric fields that either repel or attract particles in order to move them. Dielectrophoresis, for instance, can move larger numbers of particles. However, it lacks the resolution and flexibility of optical tweezers.

The UC Berkeley engineers found a way to get the best of both worlds by transforming optical energy to electrical energy through the use of a photoconductive surface. The idea is similar to that used in the ubiquitous office copier machine. In xerography, a document is scanned and transferred onto a photosensitive drum, which attracts dyes of carbon particles that are rolled onto a piece of paper to reproduce the image.

In this case, the researchers use a photosensitive surface made of amorphous silicon, a common material used in solar cells and flat-panel displays. Microscopic polystyrene particles suspended in a liquid were sandwiched between a piece of glass and the photoconductive material. Wherever light would hit the photosensitive material, it would behave like a conducting electrode, while areas not exposed to light would behave like a non-conducting insulator. Once a light source is removed, the photosensitive material returns to normal.

Depending upon the properties of the particles or cells being studied, they will either be attracted to or repelled by the electric field generated by the optoelectronic tweezer. Either way, the researchers can use that behavior to scoot particles where they want them to go.

There are many reasons why researchers would want the ability to easily manipulate cells. Biologists may want to isolate and study the fetal cells that can be found in a mother’s blood sample, for instance, or sort out abnormally shaped organisms from healthy ones.

“This sorting process is now painstakingly done by hand,” said Wu, who is also co-director of the Berkeley Sensor and Actuator Center. “A technician finds the cell of interest under a microscope and literally cuts out the piece of glass where the cell is located, taking care not to harm the sample.”

“Our design has a strong practical advantage in that, unlike optical tweezers, a simple light source, such as a light-emitting diode or halogen lamp, is powerful enough,” said Chiou, a Ph.D. student in electrical engineering and computer sciences and lead author of the paper. “That is about 100,000 times less intense than the power required for optical tweezers.”

Moreover, since the optoelectronic tweezers generate patterns through projected light, an almost limitless range of patterns are possible. Interested in boxing up individual particles in a grid-like pattern? No problem. Perhaps a star pattern would be more interesting. And there’s no reason why the light needs to be static, so the researchers have even created moving conveyor belts to show how large particles can be automatically sorted from smaller ones.

“We can almost change these patterns on the fly,” said Ohta, also a Ph.D. student in electrical engineering and computer sciences. “For other manipulation tools, changing these electrode patterns meant fabricating a new chip. Now, we can just project a new image to generate any type of pattern we want.”

The researchers also took advantage of the difference in electrical conductivity between living and dead cells. Living cells with intact membranes in a lower conductive medium are attracted to areas of exposed light. Using a series of ever shrinking concentric circles, the researchers were able to round up living human immune cells while leaving dead ones behind.

Chiou added that while researchers can use the optoelectronic tweezer to study a few single cells, they would also have the choice of manipulating roughly 10,000 cells or particles at the same time, giving statistical weight to their studies.

The researchers are now studying ways to combine this technology with computer pattern recognition so that the sorting process could be automated. “We could design the program to separate cells by size, luminescence, texture, fluorescent tags and basically any characteristic that can be distinguished visually,” said Wu.

Part of Wu’s research was conducted while he was an electrical engineering professor at UC Los Angeles, and a co-principal investigator at NASA’s Institute for Cell Mimetic Space Exploration, headquartered at UCLA’s Henry Samueli School of Engineering and Applied Science.

Media Contact

More Information:

http://www.berkeley.eduAll latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…

Making diamonds at ambient pressure

Scientists develop novel liquid metal alloy system to synthesize diamond under moderate conditions. Did you know that 99% of synthetic diamonds are currently produced using high-pressure and high-temperature (HPHT) methods?[2]…