UCSD chemists use tiny ’chaperones’ to direct molecules and nanoparticles in drop of liquid

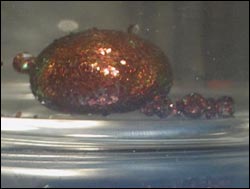

Smart dust particles self assembled on drops of oil in water. Photo Credit: Jamie Link, UCSD

Chemists at the University of California, San Diego have developed a method that uses dust-sized chips of silicon to surround and precisely direct the motion of molecules, cells, bacteria and other miniscule objects within a tiny drop of liquid.

Their development of these tiny silicon “chaperones,” detailed today in an advance online publication in a forthcoming issue of the journal Nature Materials, represents an important new achievement in the emerging field of “microfluidics,” in which new methods are sought to create, transport and experiment with ever smaller volumes of fluids.

Much as the development of smaller and smaller computer chips has transformed the electronics industry, the “smaller is better” movement of microfluidics is already beginning to pave the way for a new wave of developments in biotechnology and nanotechnology. One major problem now facing scientists in the biotechnology industry is how to handle tiny volumes of liquid containing precious samples of DNA, bacteria, viruses or other nano-sized particles without losing much of the samples.

“As the sample volume becomes smaller and smaller, the number of molecules that stick to the insides of a micropipette or any other kind of micro-channel becomes a significant fraction of the total number of molecules in the sample,” says Michael Sailor, a professor of chemistry and biochemistry who headed the UCSD effort. “This problem has spawned the idea of a ‘lab in a drop.’ A sphere has the lowest ratio of surface area to volume, so if a droplet containing the sample of interest can be manipulated without it coming into contact with the walls of its container, one can minimize the amount of material lost.”

The UCSD development took shape when Jason Dorvee, one of Sailor’s graduate students, added a magnetic iron oxide to microscopic chips of silicon fabricated in Sailor’s laboratory so that they could be easily moved about with a hand-held magnet. These tiny chips, developed several years ago by Sailor and Jamie Link, a graduate researcher in Sailor’s laboratory, are also known as “smart dust. “We call them ‘smart dust’ because their nanostructure can be engineered to give them rudimentary sensing, data processing, communication, and homing capabilities,” says Sailor, “Jason’s addition of magnetic properties allows us to direct their motion.”

Sailor and his group initially developed these microscopic sensors so they could be programmed to detect and surround specific objects like a drop of toxic chemical or a cancer cell. Their latest development now provides the scientists with the additional capability to control and move this assembly of particles and their cargo to specific areas for examination or experimentation. But of even greater importance, their method could be adapted for future industrial microfluidics processes to mix and even neutralize chemicals without the need for pumps, valves, channels or pipettes. “It’s a new way of doing microfluidics,” explains Dorvee. “With this system, you can transport tiny material suspended in water through oil efficiently without pumps and channels.”

Once he added the superparamagnetic iron oxide to the silicon to make them magnetic, Dorvee made one side of the smart dust hydrophobic, or water repelling, and the other side hydrophilic, or water loving. This process, developed last year by Link and Sailor, assured that the tiny smart dust chips would always spontaneously assemble on the outside of organic droplets, such as oil, immersed in water or water droplets immersed in oil. When the chips come into contact with different chemicals, small changes in the color of their surfaces, which are detectable using a spectrometer based on a modified digital camera, allow the scientists to remotely identify the specific chemicals encased by the smart dust.

In their experiments, the chemists were able to move these smart-dust-encased droplets with hand-held magnets precisely within liquid-filled Petri dishes. The researchers were also able to move the droplets magnetically into contact with a tiny capillary tube, where their contents could be drained, mixed with other chemicals, then refilled with a microsyringe. This capability, shown in the sequence of photos above, would be extremely useful for scientists handling tiny volumes of valuable biological molecules or for any number of future industrial microfluidics processes. “We can manipulate material that wouldn’t normally be affected by magnetic fields, such as organic and inorganic solutions, cells, DNA and proteins,” says Dorvee.

To demonstrate how the magnetic silicon chaperones could be used to perform chemistry on a miniscule scale, Dorvee encased two tiny droplets with the smart dust, one containing a solution of potassium iodide and another containing a solution of silver nitrate, in a hydrophilic organic solvent. With a spectrometer pointed at the surfaces of the two droplets, he identified the two compounds, then magnetically brought the droplets into contact. This resulted in a chemical reaction that produced silver iodide, which he was again able to identify remotely from the color changes on the surface of the chips. “With the smart dust chaperones, we can actually make little microbottles that not only contain specific chemicals, but that we can identify with a label,” says Dorvee.

Other coauthors of the paper besides Sailor and Dorvee were Sangeeta Bhatia, an associate professor of bioengineering at UCSD’s Jacobs School of Engineering, and Austin Derfus, a graduate student working in her laboratory. The project was supported by grants from the Air Force Office of Scientific Research and the National Cancer Institute.

Media Contact

More Information:

http://www.ucsd.eduAll latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…