Method produces uniform, self-assembled nanocells

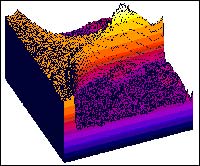

The peaks on this three-dimensional plot indicate a high concentration of liposomes forming in a microchannel.

Nanotechnology is about making improved products by building them from components hundreds of times smaller than a human blood cell. But how do you put things together at such a tiny scale? One way is to create the right conditions, so that they assemble themselves.

For example, a new method for producing uniform, self-assembled nanocells has been developed by researchers at the National Institute of Standards and Technology (NIST). Reported in the March 10 issue of the Journal of the American Chemical Society, the method may have applications as an improved method for encapsulating drug therapies. A patent application has been filed.

Current bulk methods for producing nanocells called liposomes—a type of artificial cell—produce particles in a wide range of sizes. The sizes must be sorted and filtered before being used for drug delivery, since dosage depends critically on size.

The new NIST method uses micrometer-size channels etched into a device to produce self-assembled liposomes of specific sizes from as large as about 240 nanometers (nm) to as small as about 100 nm. A stream of natural fats (lipids) dissolved in alcohol is directed at an intersection of two channels that looks like a micro version of a four-way stop. A water-based liquid containing medicines or other substances is sent toward the lipid stream from two opposing directions. Rather than mixing with the water, the lipids surround it, forming self-assembled nanocells.

Controlling flow rates in the microchannels produces nanocells of specific sizes. Faster flows produce smaller cells. Medicine-filled liposomes made in nanosizes should allow for more accurate drug delivery. In particular, liposomes have been studied for years as a way to concentrate the effectiveness of cancer chemotherapy while minimizing harmful side effects.

Media Contact

All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…