U. of Colorado team developing ’Flu Chip’ for fast, accurate diagnosis

From left to right, CU-Boulder Associate Professor Robert Kuptcha, undergraduate student Amy Reppert, graduate student Michael Townsend and team leader and Professor Kathy Rowlen of the chemistry and biochemistry department. Photo courtesy of Casey Cass, University of Colorado. The Flu Chip image was accessed from the website of Leming Shi of Jefferson, Ark.

A team of researchers at the University of Colorado at Boulder is developing a “Flu Chip” that will aid physicians in swiftly diagnosing respiratory illness for future flu seasons.

The Flu Chip will allow doctors and public health officials to differentiate between three types of influenza and other viruses that cause similar clinical symptoms, such as severe acute respiratory syndrome, or SARS.

The CU team, led by Professor Kathy Rowlen and co-principal investigator and Associate Professor Robert Kuchta of the chemistry and biochemistry department, recently received a $1.7 million grant from the National Institute of Infectious Disease to develop the chip in collaboration with the Centers for Disease Control and Prevention in Atlanta, the World Health Organization and Bio-Rad Laboratories in Hercules, Calif.

According to Rowlen, influenza A viral infections have had a dramatic impact on humans, with an estimated 500,000 deaths worldwide each year and significant economic impact resulting from direct and indirect loss of productivity during infection.

“For comparison, the corona virus that caused the recent outbreak of SARS has claimed less than 1,000 lives to date,” said Rowlen. “However, as demonstrated by the public response to SARS, of great concern is the ability of viruses to undergo natural or engineered genetic change that could result in a virus capable of rapid and lethal spread within the population.”

One of the most dramatic events in influenza history was the so-called “Spanish Flu” pandemic of 1918-1919. In less than a year, between 20 million and 40 million people died from influenza, with an estimated one fifth of the world’s population infected.

“Because it is readily transmitted, primarily as an airborne pathogen and because the virus can be genetically engineered into novel forms, influenza A also represents a serious biodefense concern,” Rowlen said.

“Rapid identification of any biological pathogen, such as flu A, anthrax or SARS, requires a reliable and relatively inexpensive analytical system that can be widely manufactured and distributed,” she said. “Current commercial technology for rapid identification of influenza A does not provide any genetic information and therefore cannot provide investigators at the CDC or the World Health Organization with adequate information for managing local epidemics or worldwide pandemics.”

DNA microarrays, which are the basis for the Flu Chip, represent a promising technology for accurate and relatively rapid pathogen identification based on genetic “signatures.”

The general structure of a DNA microarray is a well-defined arrangement of micron-sized spots on an optically flat surface, each of which contains a layer of relatively short strands of DNA designed to capture a specific genetic sequence from a sample.

Each spot — about one-thousandth of an inch across — is deposited by a robot. Patient samples can be evaluated through a fairly simple procedure called hybridization. Hybridization is achieved by heating and slowly cooling the sample processed from a patient with the microarray.

The microarray is then developed to produce an image, she said. By knowing the identity of specific DNA segments known as oligonucleotides at any location within the array, one can determine which bits of genetic information were present in the patient sample by reading the image.

The CU team of researchers is developing the Flu Chip as an inexpensive way to swiftly — within an hour or less — screen for influenza A, the most bothersome strain of flu, as well as influenza B and C, SARS and respiratory syncytial virus, which is a primary cause of respiratory illness in infants. “In addition, the Flu Chip could play a significant role in detecting and containing viral outbreaks or alerting officials to an ’engineered’ influenza virus,” Rowlen said.

Other members of the CU-Boulder Flu Chip team include post-doctoral research associate Chad Moore, graduate students Michael Townsend and James Smagala, and undergraduate student Amy Reppert.

“In order to address the needs in developing nations, one of our primary objectives is to create an inexpensive and field-portable test kit for respiratory illness,” said Rowlen. “The goal is to provide an important new tool to the World Health Organization for global screening of respiratory illness,” she said.

Media Contact

All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

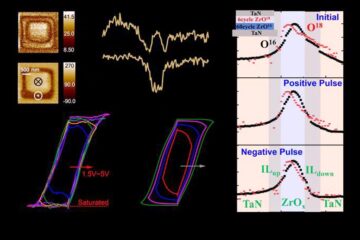

Evidence for reversible oxygen ion movement during electrical pulsing

…enabler of the emerging ferroelectricity in binary oxides. In a recent study published in Materials Futures, researchers have uncovered a pivotal mechanism driving the emergence of ferroelectricity in binary oxides….

Next-generation treatments hitch a ride into cancer cells

Researchers from Osaka University discover that opening a channel into cancer cells helps antisense oligonucleotide drugs reach their targets. Antisense oligonucleotides (ASOs) are next-generation drugs that can treat disease by…

Boron deficiency: oilseed rape reacts as with infection and pest infestation

Genetic mechanisms uncovered… Boron deficiency has a devastating effect on oilseed rape and related plants. However, little is known about the underlying genetic mechanisms. A study shows that the response…