A New Twist on DNA

Using a tool kit of lasers, tiny beads and a Lego set, Howard Hughes Medical Institute researchers have made the first measurement of the torsional, or twisting, elasticity of a single molecule of DNA.

The measurements reveal that DNA is significantly stiffer than previously thought and, when wound, may in fact provide enough power to be used as a sort of molecular, rubberband motor to propel nanomachines. Although that type of application may be well in the future, the studies are significant because they offer a blueprint for measuring the contortions that DNA undergoes during replication and other key processes.

The researchers, led by Howard Hughes Medical Institute investigator Carlos Bustamante, reported their research in the July 17, 2003, issue of the journal Nature. Bustamante and the paper’s two lead authors, graduate students Zev Bryant and Michael Stone, are at the University of California, Berkeley.

“This finding is important because many of the processes involved in reading the information in DNA involve distorting the DNA molecule,” said Bustamante. “And to truly understand these processes, we need to understand the energy costs involved in the interaction between the protein that induces distortion and the DNA.”

Almost ten years ago, Bustamante and his colleagues measured the extensional elasticity of single-strand DNA, by attaching a DNA molecule at either end to tiny beads. Using a laser “magnetic tweezers” instrument, the researchers applied a precisely known force to stretch the molecule. However, measuring the torsional stiffness of the molecule proved far more difficult.

“For almost seven years, I couldn’t convince any graduate student or postdoc to do these experiments,” said Bustamante. “I would tell them my idea, which I thought was really great, and they would look at me, smile and say, `Yeah, yeah, great, nice idea … next?’ Finally, Zev and Mike came to my office and said, `We’re going to try this crazy experiment of yours. It’s not going to work, but we’ll try it, anyway.’”

Bustamante’s scheme involved attaching the ends of a single DNA molecule between two tiny beads as they had done before. However, in the torque-measurement experiments, the researchers then biochemically “nicked” a point on the double-strand DNA to create a single chemical bond swivel. Near this nick, on the side of the rotating bead, the researchers attached a third “indicator” bead. They then rapidly wound the DNA molecule up thousands of times — while holding the rotor bead steady with flow — using a twisting robot built from Legos. After the winding process, they stopped the flow and followed the unwinding of the DNA molecule by looking at the spinning of the rotor bead in real time.

By measuring the resulting spins of a series of indicator beads of differing diameters as the molecule untwisted, the researchers obtained data that they could analyze to measure the DNA molecule’s torsional stiffness.

Bustamante and his colleagues discovered from this analysis that the DNA molecule was about 40 percent more resistant to twisting than had been reported by other researchers. “We’re very surprised and excited about this finding because it represents the first direct measurement of the torsional stiffness of a single DNA molecule,” said Bustamante. “The other measurements were done on molecules in bulk, and were indirect.”

According to Bustamante, the conclusive measurement of torsional elasticity will enable researchers to understand better the “partitioning” of mechanical energy as a DNA molecule undergoes twisting during biological processes. While some fraction of the energy twists the double-stranded spiral of the molecule itself, another fraction creates “writhing” — a hairpin looping of the molecule like an over-twisted rope. “This value of forty percent more tells us we may need to revise our ideas about such partitioning,” said Bustamante.

Importantly, he said, the ability to measure molecular torque will enable a new class of experiments to study the mechanical behavior of protein enzymes that interact with the DNA molecule. For example, Bustamante and his colleagues are now using the same experimental apparatus to explore how the enzyme DNA polymerase — which copies a single DNA strand by pulling itself along the strand’s length — exerts torque on the DNA strand as it works.

More speculative, said Bustamante, is the idea that the DNA molecule might provide energy to power molecule-sized nanomotors. “We found that if you pull the DNA molecule, it will overstretch and must unwind. During this process, the mechanical linear force applied to the end of the molecule gets transformed into the generation of torque. If you relax the molecule, it will rewind, generating torque in the opposite direction. The molecule then behaves as a reversible force-torque converter,” said Bustamante. “If you attached rotational elements to the molecule, when you pulled the molecule, it would begin rotating and would drive the molecule as a motor.”

Contact: Jim Keeley, keeleyj@hhmi.org

Media Contact

More Information:

http://www.hhmi.orgAll latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Wildfire danger to increase due to climate change

WSL Institute for Snow and Avalanche Research (SLF) researchers expect an elevated wildfire danger in the Alpine Foreland from 2040 onwards due to changing meteorological conditions. The danger currently remains…

Advanced Brain Science Without Coding Expertise

Researchers at Helmholtz Munich and the LMU University Hospital Munich introduce DELiVR, offering a new AI-based approach to the complex task of brain cell mapping. The deep learning tool democratizes…

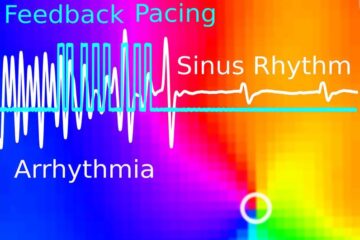

Gentle defibrillation for the heart

Using light pulses as a model for electrical defibrillation, Göttingen scientists developed a method to assess and modulate the heart function. The research team from the Max Planck Institute for…