From stem cells to organs: The bioengineering challenge

To do this, he has been applying engineering principles to stem cell research – work that has just earned him recognition by the American Association for the Advancement of Science (AAAS). The society will induct him as a Fellow during its Annual Conference, being held in Boston from February 14 to 18.

Starting with computer models of stem cell growth and differentiation (the process by which a stem cell matures into its final form), Zandstra has moved on to develop more sophisticated culture methods that fine-tune the microenvironments to guide the generation of the different cells types that make up the mature cells in our tissues: heart cells for the heart or blood cells for blood.

“If you describe something mathematically, you have a much better understanding of it than if you just observe it,” he says. “And it's also a powerful way to test many different hypotheses in silico before going into the lab and doing the much more difficult experiments in vitro.”

Dr. Zandstra, the Canada Research Chair in Stem Cell Bioengineering, also held a prestigious NSERC Steacie Fellowship. The Steacie prize – which goes to six select Canadian professors annually – allowed Zandstra to extend his work from mouse to man.

“There's only so much we can do with mouse cells,” notes Dr. Zandstra. “Now if we can also figure out how to get human embryonic stem cells to differentiate on command to generate functional adult-like cells, you can begin to think about the kinds of medical conditions you could treat with them.”

Media Contact

More Information:

http://www.nserc.caAll latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Wildfire danger to increase due to climate change

WSL Institute for Snow and Avalanche Research (SLF) researchers expect an elevated wildfire danger in the Alpine Foreland from 2040 onwards due to changing meteorological conditions. The danger currently remains…

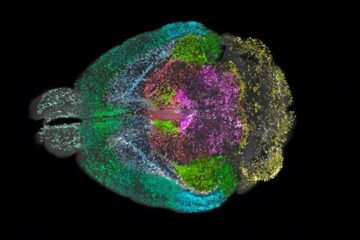

Advanced Brain Science Without Coding Expertise

Researchers at Helmholtz Munich and the LMU University Hospital Munich introduce DELiVR, offering a new AI-based approach to the complex task of brain cell mapping. The deep learning tool democratizes…

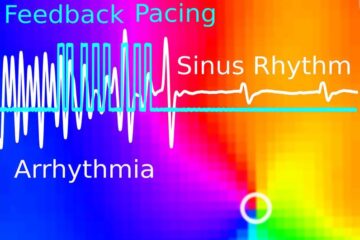

Gentle defibrillation for the heart

Using light pulses as a model for electrical defibrillation, Göttingen scientists developed a method to assess and modulate the heart function. The research team from the Max Planck Institute for…