Penn Researchers Help Nanoscale Engineers Choose Self-Assembling Proteins

The team was led by postdoctoral fellow Gevorg Grigoryan and professor William DeGrado of the Department of Biochemistry and Biophysics in Penn’s Perelman School of Medicine, as well as graduate student Yong Ho Kim of the Department of Chemistry in Penn’s School of Arts and Sciences. Their colleagues included members of the Department of Physics and Astronomy in SAS.

Their research was published in the journal Science.

The team set out to design proteins that could wrap around single-walled carbon nanotubes. Consisting of a cylindrical pattern of carbon atoms tens of thousands of times thinner than a human hair, nanotubes are enticing to nanoengineers as they are extraordinarily strong and could be useful as platform for other nano-structures.

“We wanted to achieve a specific geometric pattern of the atoms that these proteins are composed of on the surface of the nanotube,” Grigoryan said. “If you know the underlying atomic lattice, it means that you know how to further build around it, how to attach things to it. It's like scaffolding for future building.”

The hurdle in making such scaffolds isn’t a lack of information, but a surfeit of it: researchers have compiled databases that list hundreds of thousands of actual and potential protein structures in atomic detail. Picking the building materials for a particular structure from this vast array and assuring that they self-assemble into the desired shape was beyond the abilities of powerful computers, much less humans.

“There's just an enormous space of structural possibilities to weed through trying to figure out which are feasible,” Grigoryan said. “To have a process that can do that quickly, that can look at a structure and say ‘that's not reasonable, that can't be built out of common units,’ would solve that problem.”

The researchers’ algorithm works in three steps, which, given the parameters of the desired scaffolding, successively eliminate proteins that will not produce the right shape. The elimination criteria were based on traits like symmetry, periodicity of binding sites and similarity to protein “motifs” found in nature.

After separating the wheat from the chaff, the result is a list of thousands of candidate proteins. While still a daunting amount, the algorithm makes the protein selection process merely difficult, rather than impossible.

The research team tested their algorithm by designing a protein that would not only stably wrap around a nanotube in a helix but also provide a regular pattern on its exterior to which gold particles could be attached.

“You could use this to build a gold nanowire, for instance, or modulate the optical properties of the underlying tube in desired ways” Grigoryan said.

Next steps will include applying this algorithm for designing proteins that can attach to graphene, which is essentially an unrolled nanotube. Being able to make scaffolds out of customizable array of proteins in a variety of shapes could lead to advances in everything from miniaturization of circuitry to drug delivery.

Engineering these materials in the lab requires a tremendous amount of precision and computational power, but such efforts are essentially mimicking a phenomenon found in even the simplest forms of life.

“The kind of packing that certain viruses have in their viral envelope is similar to what we have here in that they self-assemble. They have protein units that, on their own, form their complicated structures with features that are far beyond the size of any single protein,” Grigoryan said. “Each protein doesn’t know what the final structure is going to be, but it still helps form it. We were inspired by that.”

In addition to Grigoryan, DeGrado and Kim, researchers included Rudresh Acharya of the Department of Biochemistry and Biophysics in the Perelman School of Medicine and Kevin Axelrod, Rishabh M. Jain, Lauren Willis, Marija Drndic and James M. Kikkawa of the Department of Physics and Astronomy in SAS.

Their research was supported by the National Science Foundation and the National Institutes of Health.

Media Contact

More Information:

http://www.upenn.eduAll latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…

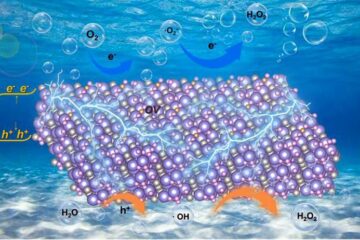

Oxygen vacancies mediated ultrathin Bi4O5Br2 nanosheets

… as efficient piezocatalyst for synthesis of H2O2 from pure water. As an important chemical raw material, hydrogen peroxide (H2O2) is widely applied in various aspects of industry and life….