Miniature Arm Lifts Weights

<br>

A small plastic strip can do “weight training” to effortlessly lifts many times its own weight, driven by cyclic changes in the humidity of the surrounding air.

This strong “artificial arm” is based on the interaction between microgels and a layer of polycations that shrinks as it dries, according to a report presented by Canadian researchers in the journal Angewandte Chemie.

Polymer materials that perform work in response to a chemical or physical stimulus are often called “artificial muscles”.

These are very interesting for a number of applications, including controlling the movements of “gentler” robots. All components of such robots need to be soft and flexible so that they don’t damage delicate objects and can move in tight spaces.

The arm developed by researchers working with Michael J. Serpe at the University of Alberta is constructed in the following way: A strip of a plastic film is coated with chromium and gold, followed by a microgel monolayer.

Microgels are cross-linked polymers that swell up with a solvent such as water to form gel particles with diameters of up to a few micrometers. The Canadian researchers used negatively charged microgels made from poly(N-isopropylacrylamide) and acrylic acid. A solution containing polycations is deposited onto the gel. These act as positive counterions.

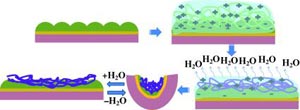

When this system dries out, the hydrophobic interactions between the hydrocarbon regions of the polymer cations increase considerably, which causes the layer containing the polymer cations to shrink. Because the electrostatic attraction between the polycations and the microgel is very strong and the microgel layer is very firmly attached to the coated sheet of plastic, the ends of the strip bend upwards and the system curls up. When the air humidity is increased, it stretches back out.

The researchers hung one of their strips up in a chamber with controlled humidity conditions. By changing the humidity, they were able to make their artificial arm “grip” the handle of a small package and to “hold on” as it rose up. In another experiment, they hung a chain of paperclips to the end of one extended mini-arm. Cyclic changes in the humidity caused the arm to raise and lower this weight, which was 14 times as heavy as the arm itself, like a miniature weight-lifting exercise.

“Given that a human arm is approximately 6.5 % of the total mass of the human body, this is equivalent to a 75 kg human with a single arm that is capable of lifting 68.3 kg,” Serpe says to illustrate the strength of his miniature arm. Even hanging 52.2 g of weight from a curled-up arm was not enough to stretch it out. If a 75 kg human wanted to achieve a similar feat, he would have to keep his arm bent even with 1280 kg pulling on it.

About the Author

Dr. Michael J. Serpe is an assistant professor in the Department of Chemistry at the University of Alberta. His research is focused on using polymer-based materials for a variety of applications; with a particular focus on developing novel point-of-care diagnostics, water remediation systems, and polymer-based muscles and actuators. He was recently awarded the Petro-Canada Young Innovator Award for his research accomplishments.

Author: Michael J. Serpe, University of Alberta, Edmonton (Canada), http://www.chemistry.ualberta.ca/FacultyandStaff/Faculty/MichaelSerpe.aspx

Title: Polymer-Based Muscle Expansion and Contraction

Angewandte Chemie International Edition, Permalink to the article: http://dx.doi.org/10.1002/anie.201303475

Copy free of charge. We would appreciate a transcript of your article or a reference to it.

The original article is available from our online pressroom at http://pressroom.angewandte.org.

Media Contact

More Information:

http://pressroom.angewandte.orgAll latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Combatting disruptive ‘noise’ in quantum communication

In a significant milestone for quantum communication technology, an experiment has demonstrated how networks can be leveraged to combat disruptive ‘noise’ in quantum communications. The international effort led by researchers…

Stretchable quantum dot display

Intrinsically stretchable quantum dot-based light-emitting diodes achieved record-breaking performance. A team of South Korean scientists led by Professor KIM Dae-Hyeong of the Center for Nanoparticle Research within the Institute for…

Internet can achieve quantum speed with light saved as sound

Researchers at the University of Copenhagen’s Niels Bohr Institute have developed a new way to create quantum memory: A small drum can store data sent with light in its sonic…