Micro-Patchwork Family

<br>

Micromachines, nanorobots, multifunctional drug transporters, and matrices for tissue growth – these and many other applications would benefit from three-dimensional microstructures that present different (bio)chemical ligands that offer control over directionality.

In the journal Angewandte Chemie, a team of German and American researchers has now reported the production of microparticles whose surface consists of three separate areas (“patches”) that can be decorated with three different (bio)molecules.

“While the spatially controlled presentation of chemical and biological ligands is well established for two-dimensional substrates, very few methodologies exist for the spatially controlled decoration of three-dimensional objects, such as microparticles,” explains Jörg Lahann (University of Michigan, USA and Karlsruhe Institute of Technology). “Such structures would be very useful for many different applications, such as the controlled interaction of particles with biological cells for tissue growth.”

Organs are three-dimensional structures made of different types of cells. The growth of organs requires supports that stimulate the three-dimensionally controlled colonization of these cell types. Future technical applications, such as micromachines, will require 3D particles that can control the self-assembly of three-dimensional structures. If an area can also be made to respond to a stimulus by swelling or shrinking, for example, it would be possible to produce movable miniature components for use in sensors, robotic arms, or switchable drug transporters.

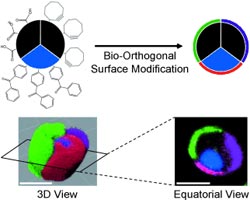

Lahann and his co-workers have now developed a method that allows them to obtain three chemically different patches on the same microparticle. The technique they used is electrohydrodynamic co-jetting, a process in which the researchers pump three different polymer solutions through parallel capillaries. An electric field accelerates the ejected liquid, which stretches it out. The solvent simultaneously evaporates, leaving behind a microfiber consisting of three chemically different compartments. By cutting the fibers, the team produces fine microparticles that are also made of three chemically different segments.

For their starting materials, the researchers chose three biodegradable polymers based on lactic acid. The three polymers were each equipped with a different chemical anchor group (known as “click functionality”).

It was thus possible to attach different ligands, such as different biomolecules, to the anchor groups in an orthogonal fashion, meaning that the surface reactions to attach the ligands do not influence each other. By using biomolecules containing fluorescent markers, the scientists were able to demonstrate by using a microscope that three different patches were indeed present on the same microparticle. “For practical applications the particles need to be just a bit smaller – that is our next goal,” says Lahann.

About the Author

Dr. Lahann is Professor of Chemical Engineering, Materials Science and Engineering and Biomedical Engineering at the University of Michigan. He also serves as the Director of the Biointerfaces Institute at the University of Michigan and the Co-Director of the Institute for Functional Interfaces at the Karlrsruhe Institute of Technology, Germany. He has been selected byTechnology Review as one of the top 100 young innovators and is the recipient of the 2007 Nanoscale Science and Engineering Award as well as a NSF-CAREER award. Since 2011, he has been a fellow of the American Institute of Medical and Biological Engineering.

Author: Joerg Lahann, University of Michigan, Ann Arbor (USA), http://www.umich.edu/~lahannj/index.htm

Title: Chemically Orthogonal Three-Patch Microparticles

Angewandte Chemie International Edition, Permalink to the article: http://dx.doi.org/10.1002/anie.201310727

Media Contact

More Information:

http://pressroom.angewandte.orgAll latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Combatting disruptive ‘noise’ in quantum communication

In a significant milestone for quantum communication technology, an experiment has demonstrated how networks can be leveraged to combat disruptive ‘noise’ in quantum communications. The international effort led by researchers…

Stretchable quantum dot display

Intrinsically stretchable quantum dot-based light-emitting diodes achieved record-breaking performance. A team of South Korean scientists led by Professor KIM Dae-Hyeong of the Center for Nanoparticle Research within the Institute for…

Internet can achieve quantum speed with light saved as sound

Researchers at the University of Copenhagen’s Niels Bohr Institute have developed a new way to create quantum memory: A small drum can store data sent with light in its sonic…